Stainless Steel Multi-disc Screw Press

The double screw type sludge dehydrator belongs to the screw press dehydrator, which can reduce the sedimentation tank and sludge concentration tank, and save the construction cost of the sewage station.

Send Inquiry1.Stainless steel multi-disc screw press Introduction

The double screw type sludge dehydrator belongs to the screw press dehydrator, which can reduce the sedimentation tank and sludge concentration tank, and save the construction cost of the sewage station. The double screw type sludge dehydrator cleverly uses the multi ring automatic cleaning and filtering technology instead of the traditional filter screen filtration.

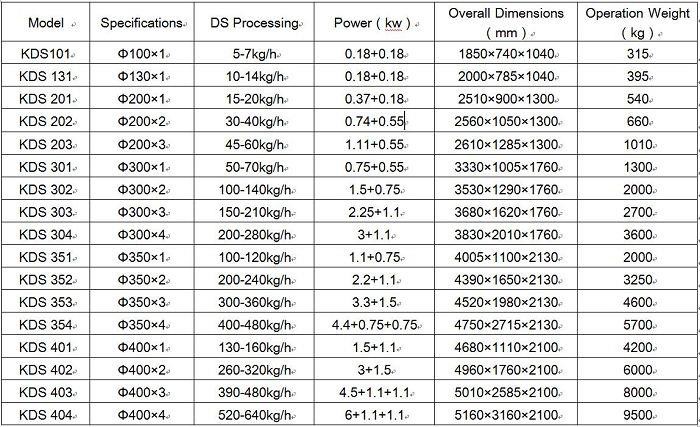

2.Technical parameters

3.Product detail

Original: Jiangsu, China

Certification: ISO9001, ISO14001, etc.

Price: Negotiable

Material: SUS304/SUS316

Voltage: 380V 50Hz, the voltage can be as local demand

Payment term: TT, LC

Delivery date: Negotiable

Packing: export standard

Market: Middle East/ Africa/Asia/South America/Europe/North America

Warranty: 1 year

MOQ: 1 set

4.Product Advantage

The self-cleaning and filtering technology ensures the continuous and stable sludge water separation effect of the dehydrator. Through the strong extrusion pressure generated by the screw diameter and screw pitch changes, as well as the tiny gap between the floating ring and the fixed ring, the sludge can be extruded and dehydrated. It is a new type of solid-liquid Separation equipment.

5.Construction principle

1). The main body of the dehydrator is a filter device composed of fixed rings and traveling rings, in which the spiral shaft runs through. The front section is the concentration section, and the back section is the dehydration section.

2). The filter gap formed between the fixed ring and the traveling ring and the pitch of the screw axis gradually decrease from the concentration part to the dehydration part.

3). The rotation of the screw shaft drives the sludge to be transported from the concentration part to the dehydration part, and at the same time, it also continuously drives the traveling ring to clean the filter joint to prevent clogging.

4). After gravity concentration in the concentration section, sludge is transported to the dehydration section. In the process of advance, with the gradual decrease of filter joint and screw pitch, and the blocking effect of back pressure plate, a great internal pressure is generated, and the volume is constantly reduced, so as to achieve the purpose of full dehydration.

6.Dehydration principle

Sludge is transported to the dehydration section after gravity concentration in the concentration section. In the process of advance, with the gradual reduction of the filter joint and pitch, and the blocking effect of the back pressure plate, internal pressure is generated, and the volume is continuously reduced, so as to achieve the purpose of full dehydration. ,

Note: the replacement time of vulnerable products is an approximate value. In the actual operation process, the type of sludge, treatment method, operation adjustment and daily operation time,

It will affect the replacement cycle of vulnerable parts. (the replacement cycle of vulnerable parts is calculated based on the operation time of 365 days / year and 8 hours / day.)

Hot Tags: stainless steel multi-disc screw press, China, suppliers, manufacturers, factory, customized, price, OEM