Stainless Multi Disc Screw Press For Sludge Dewatering

The high moisture content of the sludge dewatering machine will affect the use of the machine. To reduce the moisture content of the sludge dewatering machine, we must first consider the factors affecting the sludge dryness of the sludge dewatering machine.

Send InquiryIntroduction

The high moisture content of the sludge dewatering machine will affect the use of the machine. To reduce the moisture content of the sludge dewatering machine, we must first consider the factors affecting the sludge dryness of the sludge dewatering machine. The main factors affecting the sludge dryness of the sludge dewatering machine are: 1 , The nature of the sludge 2, the flocculation effect of the sludge 3, the filtering length of the stacked screw filtering body 4, the rotating speed of the stacked screw spindle 5, the back pressure gap of the back pressure plate.

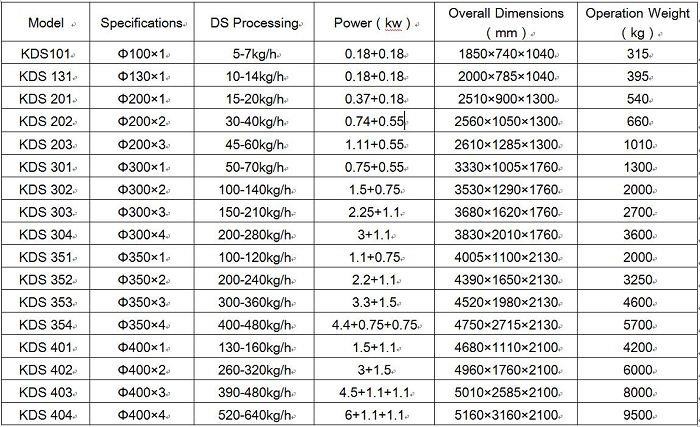

Technical parameters

Product detail

Original: Jiangsu, China

Certification: ISO9001, ISO14001, etc.

Price: Negotiable

Material: SUS304/SUS316

Voltage: 380V 50Hz, the voltage can be as local demand

Payment term: TT, LC

Delivery date: Negotiable

Packing: export standard

Market: Middle East/ Africa/Asia/South America/Europe/North America

Warranty: 1 year

MOQ: 1 set

Equipment characteristics

The main body of the multi disc sludge press dewatering machine is a filtering device formed by stacking a fixed ring and a floating ring on each other into a cylinder, and a spiral shaft penetrating it. Because the inner diameter of the screw shaft is larger than the inner diameter of the travel ring, the rotation of the screw shaft will drive the travel ring to make a circular motion to prevent blockage. The gap between the fixed ring and the swimming ring gradually decreases along the direction of the mud cake exit from the thickening section to the dewatering section. The sludge is concentrated by gravity in the concentration section, and then transported to the dewatering section, where the discharge port is forcedly dewatered by the internal pressure of the pressure plate.

1. Concentration: When the screw driving shaft rotates, the multiple solid-moving laminations located on the periphery of the driving shaft move relative to each other. Under the action of gravity, water is filtered out from the gap between the relatively moving laminations to achieve rapid concentration.

2. Dehydration: The concentrated sludge moves forward continuously with the rotation of the screw shaft; along the direction of the mud cake exit, the pitch of the screw shaft of the stacked screw sludge dehydrator gradually becomes smaller, and the gap between the rings gradually becomes smaller. As the volume of the spiral cavity becomes smaller, the internal pressure gradually increases under the effect of the back pressure plate at the outlet. With the continuous operation of the spiral driving shaft, the water in the sludge is squeezed out and the solid content of the filter cake is continuously Raise, and finally achieve continuous dehydration of sludge.

3. Self-cleaning: The rotation of the screw shaft and the stacked screw sludge dewatering machine promote the continuous rotation of the swimming ring. The equipment relies on the movement between the fixed ring and the swimming ring to achieve a continuous self-cleaning process, thereby cleverly avoiding traditional dehydration. Machine is a common problem.

4. With self-cleaning function. There is no need to clean the filter to prevent clogging, reduce the amount of flushing water, and reduce the burden on the internal circulation.

5. Through the electric control cabinet, the stacked screw sludge dewatering machine is linked with the bubble medicine machine, the mud pump, the dosing pump, etc., to achieve continuous unmanned operation for 24 hours.

Hot Tags: stainless multi disc screw press for sludge dewatering, China, suppliers, manufacturers, factory, customized, price, OEM