Multi Disc Screw Press Sludge Dewatering Machine

The multi disc press sludge dewatering machine produced by our company has diversified specifications and series, and can choose the appropriate model according to different scale projects. The working principle of the multi disc press sludge dewatering machine is very...

Send InquiryIntroduction

The multi disc press sludge dewatering machine produced by our company has diversified specifications and series, and can choose the appropriate model according to different scale projects. The working principle of the multi disc press sludge dewatering machine is very simple. The front section is a condensed structure. When the spiral porridge rotates at high speed, it drives the surrounding swimming ring to move together. Under the action of gravity, water is filtered out from the moving swimming ring Fast concentration.

The main body of the multi disc press sludge dewatering machine is laminated by a fixed ring and a floating ring, a spiral shaft runs through it, and integrates concentration and dehydration. The front section is the concentration section and the rear section is the dewatering section.

1) Concentration: When the screw shaft rotates, the multiple solid-moving laminations located on the periphery of the screw shaft move relative to each other. Under the action of gravity, sewage is filtered out from the gaps of the relative moving laminations to achieve rapid concentration.

2) Dehydration: The concentrated sludge moves forward with the rotation of the screw shaft; along the direction of the mud cake outlet, the pitch of the screw shaft gradually becomes smaller, the gap between the rings becomes smaller, and the volume of the spiral cavity becomes smaller. Constant shrinkage; under the action of the back pressure plate at the outlet, the internal pressure gradually increases. Under the continuous operation of the screw drive shaft, the water in the sludge is squeezed and discharged, and the solid content of the filter cake is continuously increased to achieve the sludge. Continuous dehydration.

3) Self-cleaning: The rotation of the screw shaft promotes the continuous rotation of the swimming ring. The device relies on the movement between the fixed ring and the swimming ring to achieve a continuous self-cleaning process, thereby cleverly avoiding the problem of blockages commonly existing in traditional dehydrators.

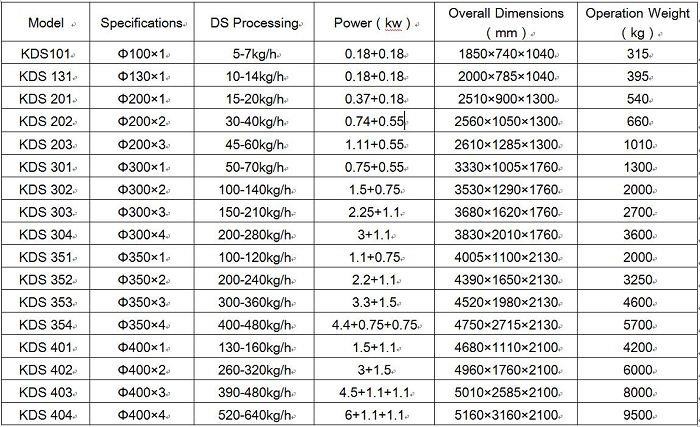

Technical parameters

Product detail

Original: Jiangsu, China

Certification: ISO9001, ISO14001, etc.

Price: Negotiable

Material: SUS304/SUS316

Voltage: 380V 50Hz, the voltage can be as local demand

Payment term: TT, LC

Delivery date: Negotiable

Packing: export standard

Market: Middle East/ Africa/Asia/South America/Europe/North America

Warranty: 1 year

MOQ: 1 set

Our Advantages

a. Extensive production experience: we are specialized in Filter Floors ABS Filter Floors with an experience of 10 years.

b. Short Delivery time: If one container 15-20 days. We also stock some standard-sized tubes and rods, if you need 3-5 pcs, we can delivery soon.

c. Safe packing: anti-rust oil be spread on tubes and rods before shipping, plastic caps on tube ends to protect inside surface, each rod be protected with cardboard tube. Finally be packed with seaworthy package or in wooden case.

Hot Tags: multi disc screw press sludge dewatering machine, China, suppliers, manufacturers, factory, customized, price, OEM