Sludge Dewatering Press

The multi disc press sludge dewatering machine is widely used in municipal sewage, food, beverage, chemical, leather, welding materials, papermaking, printing and dyeing, pharmaceutical and other industries. It saves costs and is suitable for dehydration of high and low...

Send InquiryIntroduction

The multi disc press sludge dewatering machine is widely used in municipal sewage, food, beverage, chemical, leather, welding materials, papermaking, printing and dyeing, pharmaceutical and other industries. It saves costs and is suitable for dehydration of high and low concentration sludge. When low-concentration (2000mg / L ~) sludge is dewatered, there is no need to build a concentration tank or storage tank, which reduces the construction cost, reduces the release of phosphorus and the generation of anaerobic odor. His small design, compact design, small footprint, easy maintenance and replacement; small weight, easy to carry. It can reduce the space and construction cost of the dehydrator itself.

The multi disc press sludge dewatering machine is not easy to block and has a self-cleaning function. Reduces the burden of washing water and internal circulation, and is good at dehydration of oily sludge. Its low speed operation, the rotation speed of the screw shaft is about 2 ~ 3 rpm, and the electrode consumption is low. Less breakdown, low noise and vibration, safe operation.

The multi disc press sludge dewatering machine is easy to operate. It is linked with a medicine infusion machine, a mud pump, a dosing pump, etc. through an electric control cabinet to achieve continuous unmanned operation for 24 hours. Daily maintenance time is short, reducing labor costs. It is durable, and the body is almost entirely made of stainless steel, which can extend the service life to a maximum extent.

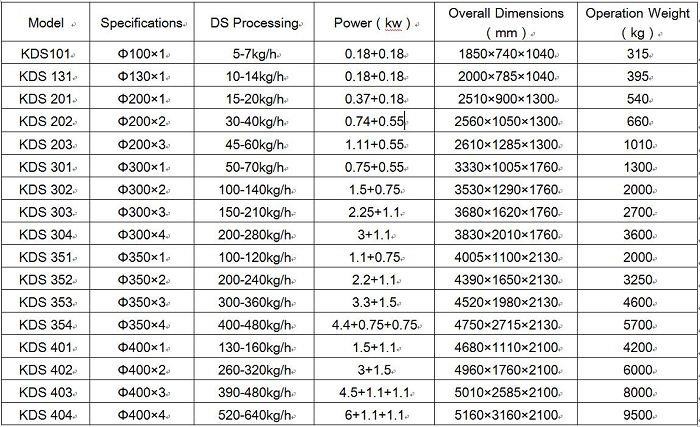

Technical parameters

Product detail

Original: Jiangsu, China

Certification: ISO9001, ISO14001, etc.

Price: Negotiable

Material: SUS304/SUS316

Voltage: 380V 50Hz, the voltage can be as local demand

Payment term: TT, LC

Delivery date: Negotiable

Packing: export standard

Market: Middle East/ Africa/Asia/South America/Europe/North America

Warranty: 1 year

MOQ: 1 set

Equipment characteristics

The selection of the multi disc press sludge dewatering machine pump should be based on the process flow, water supply and drainage requirements, and considered from five aspects, namely the liquid transfer volume, equipment lift, liquid properties of the screw press machine, pipeline layout and operating conditions. Flow is one of the important performance data of pump selection. The multi disc press sludge dewatering machine is directly related to the production capacity and conveying capacity of the entire equipment. The diaphragm filter press consists of a diaphragm plate and a box-type filter plate. The slurry is fed into the filter chamber under the pressure of the feed pump.

Clean once every five months, using the nets of the multi disc press sludge dewatering machine manufacturer and the low water content of the extruded solids. If it is found in the work that the liquid discharged from the liquid outlet is reduced or the water content of the discharged solid is high, it can be stopped and started for several times. When cleaning, first remove the bolt at the discharge port, then remove the screen, and clean the blockage in the screen with water and a copper wire brush. It is particularly noteworthy to maintain the original orientation of the screen and remove it. Please pay attention to the orientation of the screen of the screen together. It is easy to mark. The stacked screw sludge dewatering device still maintains the original orientation. Otherwise, the screen will be abraded in future work. Naturally, Will affect the output power of the extruder.

Hot Tags: sludge dewatering press, China, suppliers, manufacturers, factory, customized, price, OEM