Industrial Sludge Multi Plate Screw Thickener

At present, the belt filter press is widely used in sludge dewatering in China, but it has the problems of large water consumption and high operation requirements.

Send Inquiry1.Industrial sludge multi plate screw thickener Introduction

In general, different kinds of water containing sludge are produced in water treatment process. Sludge preparation is mainly to reduce the moisture content of sludge, reduce the moisture content, reduce the sludge volume, and bring convenience for subsequent treatment or disposal of sludge. Sludge dewatering equipment can be generally divided into belt filter press, centrifugal dehydrator, plate and frame filter press and stacked screw sludge dehydrator.

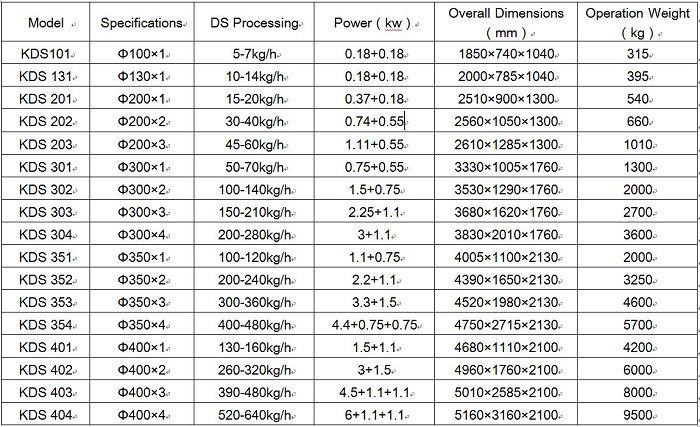

2.Technical parameters

3.Product detail

Original: Jiangsu, China

Certification: ISO9001, ISO14001, etc.

Price: Negotiable

Material: SUS304/SUS316

Voltage: 380V 50Hz, the voltage can be as local demand

Payment term: TT, LC

Delivery date: Negotiable

Packing: export standard

Market: Middle East/ Africa/Asia/South America/Europe/North America

Warranty: 1 year

MOQ: 1 set

4.Equipment characteristics

At present, the belt filter press is widely used in sludge dewatering in China, but it has the problems of large water consumption and high operation requirements. As a new type of sludge dewatering equipment, the double screw sludge dewatering machine is rapidly recognized and accepted by the market due to its advantages of energy saving, stability and high degree of automation.

The screw press is a new kind of solid-liquid separation equipment, which uses the principle of screw extrusion, through the strong extrusion pressure caused by the change of screw diameter and screw pitch, and the tiny gap between the floating ring and the fixed ring to realize the extrusion dehydration of sludge.

The main body of the sludge dehydrator is composed of multiple fixed rings and floating rings, and the spiral shaft runs through the filter device formed therein. The front section is the concentration section, and the section is the dehydration section, which completes the sludge thickening and squeezing dehydration in one cylinder, replacing the traditional filter cloth and centrifugal filtering mode with a unique and delicate filter body mode

After gravity concentration in the concentration section, the sludge is transported to the dehydration section. In the process of advance, with the gradual reduction of the filter joint and screw pitch, and the blocking effect of the back pressure plate, the sludge will generate great pressure, and the volume will continue to shrink, so as to achieve the purpose of full dehydration.

5.Application

1). Wide range of application

Widely used in municipal sewage, food, beverage, slaughtering and breeding, printing and dyeing, petrochemical, papermaking, leather, pharmaceutical and other industries sludge dehydration.

The unique dehydration principle makes the equipment suitable for high and low concentration sludge. Starting from 2000m / L, it has created a precedent for direct dehydration of low concentration sludge. The innovative structure design makes the equipment suitable for all kinds of sludge with high and low viscosity, especially oily sludge, which can be called the edge of oily sludge dewatering!

2). The equipment is not easy to block the unique dynamic and static ring filter joint structure, which makes the equipment not easy to block. There is no need to conduct a large number of cleaning to prevent the filter joint from blocking, so as to thoroughly reduce the water consumption for flushing, reduce the burden of internal circulation, and solve the problems brought by the traditional dehydration equipment blocking to the enterprise.

3). Continuous automatic operation

The sludge dewatering machine pumps sludge, adds medicine liquid and discharges sludge cake by automatic control. It is linked by electric control cabinet, dosing device, mud pump, dosing pump, etc. it does not need personnel to operate the equipment, and the operation will not be blocked, deviated by filtration or other phenomena affecting process safety. The daily maintenance is simple, and it can be operated continuously by nobody for 24 hours. For the first time, the continuous and automatic operation of sludge dewatering has been realized.

4). Save operation cost

Integrated compact design, saving operation cost; low speed spiral extrusion, greatly saving electricity cost; equipment is not blocked, greatly saving water cost; fully automatic unmanned operation, saving labor cost.

5). No secondary pollution

The rotating speed of the screw shaft is about 2-3 rpm, with small vibration and very low noise; its stacked body has the self-cleaning function, which will not cause blockage, only needs a small amount of water to wash, without secondary pollution; in addition, the sludge operates at such a slow working state, and the odor does not spread, so it creates a very comfortable operating environment.

6). Light and durable body

Due to the direct use of mechanical extrusion dehydration, without the need for large-scale bodies such as rollers, the machine is designed to be quite light; almost all the bodies are made of stainless steel, and the replacement parts are only spiral shafts and traveling rings, with long service life and durability.

7). Saving project investment

The double screw sludge dehydrator has the function of sludge concentration, which can directly treat the aerobic sludge in the aeration tank, without the need of concentration and storage unit, so as to reduce the overall floor space and construction cost of the sewage treatment facilities.

8). Improve phosphorus removal function

When sludge is dehydrated under aerobic conditions, phosphorus release from sludge in traditional sludge concentration tank or storage tank will not occur under anoxic or anaerobic conditions, so as to improve the phosphorus removal function of the whole sludge treatment system.

Hot Tags: industrial sludge multi plate screw thickener, China, suppliers, manufacturers, factory, customized, price, OEM