Multi-disc Screw Press Sludge Dewatering Machine

Under the condition of fully automatic operation, the dehydrator can realize high-efficiency flocculation, continuously complete sludge thickening and pressing dehydration, and finally return or discharge the collected filtrate.

Send Inquiry1. Introduction

The stacked screw sludge dehydrator follows the principles of force water co direction, thin layer dehydration, proper pressure and extension of dehydration path, solves the technical problems of previous generations of sludge dehydration equipment, such as easily blocked, unable to deal with low concentration sludge and oily sludge, high energy consumption, complex operation, etc., and achieves the dehydration goal of high efficiency and energy saving.

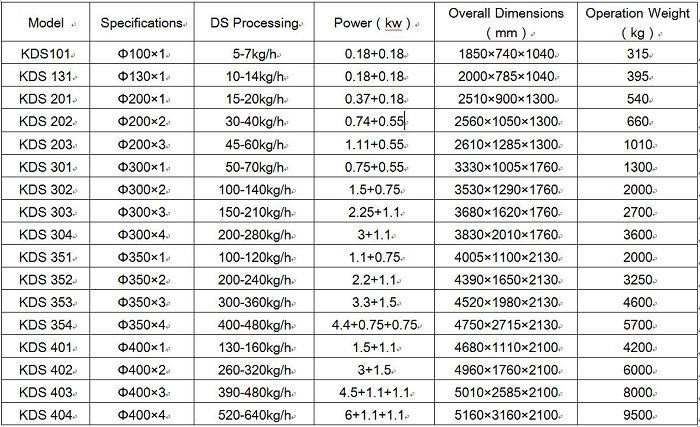

2.Technical parameters

3.Product detail

Original: Jiangsu, China

Certification: ISO9001, ISO14001, etc.

Price: Negotiable

Material: SUS304/SUS316

Voltage: 380V 50Hz, the voltage can be as local demand

Payment term: TT, LC

Delivery date: Negotiable

Packing: export standard

Market: Middle East/ Africa/Asia/South America/Europe/North America

Warranty: 1 year

MOQ: 1 set

4.Application

Under the condition of fully automatic operation, the dehydrator can realize high-efficiency flocculation, continuously complete sludge thickening and pressing dehydration, and finally return or discharge the collected filtrate. It is widely used in municipal sewage treatment engineering and water treatment system in food, starch, oil, pharmaceutical, chemical, paper, leather and other industries.

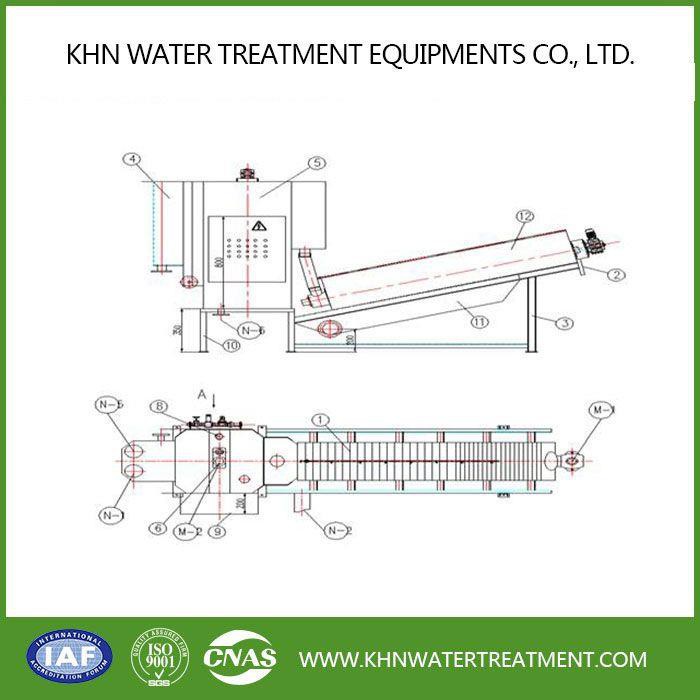

5.Structure principle

The screw type sludge dehydrator integrates automatic control cabinet, flocculation and conditioning tank, sludge thickening and dehydration body and liquid tank. The main body is a filtering device which is composed of a fixed ring and a floating ring which are overlapped with each other and a spiral axis runs through them. The front section is the concentration section and the back section is the dehydration section. The filter joint formed between the fixed ring and the traveling ring and the screw pitch of the screw shaft gradually decrease from the concentration part to the dehydration part. The screw shaft continuously drives the ring to clean the filter joint to prevent blockage. When the rotation of the screw shaft drives the sludge to be transported from the thickening section to the dewatering section, as well as the blocking effect of the back pressure plate, great internal pressure is generated and the volume is continuously reduced to achieve the purpose of full dewatering.

The double screw type sludge dehydrator can deal with the oily sludge, the low concentration sludge, the continuous and automatic operation, the cleaning water consumption is less, the secondary pollution can be restrained, and the maintenance is simple. The stacked screw type sludge dehydrator produced by our company is a small-sized combined machine that sets the relevant equipment and control cabinet on the same base, so the installation is very simple, and because of the low output power, it also has the effect of energy saving. The double screw type sludge dehydrator can operate automatically by simple operation, and can operate continuously unattended by using high polymer flocculant (liquid product) dissolving device; because the structure of the double screw type sludge dehydrator will not be blocked, there is no problem of recovery and cleaning due to capacity reduction, and only sludge oozing from the dehydration part needs to be cleaned Just rinse.

Hot Tags: multi-disc screw press sludge dewatering machine, China, suppliers, manufacturers, factory, customized, price, OEM