Multi Disc Vertical Sludge Press Filter

Multi disc vertical sludge press filter is a new type of sludge treatment equipment for filter press, which is composed of ring piece and screw shaft.

Send Inquiry1.Multi disc vertical sludge press filter Introduction

Multi disc vertical sludge press filter is a new type of sludge treatment equipment for filter press, which is composed of ring piece and screw shaft. The moving of the middle of the ring piece makes the whole process of self-cleaning in the middle of the ring piece gap, so it is not easy to block. Unlike the plate and frame dehydrator or the accumulation type dehydrator, the filter cloth of the filter press is used for filtering.

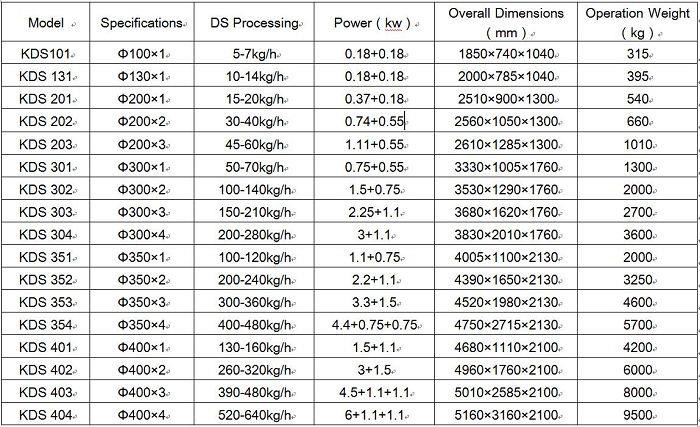

2.Technical parameters

3.Product detail

Original: Jiangsu, China

Certification: ISO9001, ISO14001, etc.

Price: Negotiable

Material: SUS304/SUS316

Voltage: 380V 50Hz, the voltage can be as local demand

Payment term: TT, LC

Delivery date: Negotiable

Packing: export standard

Market: Middle East/ Africa/Asia/South America/Europe/North America

Warranty: 1 year

MOQ: 1 set

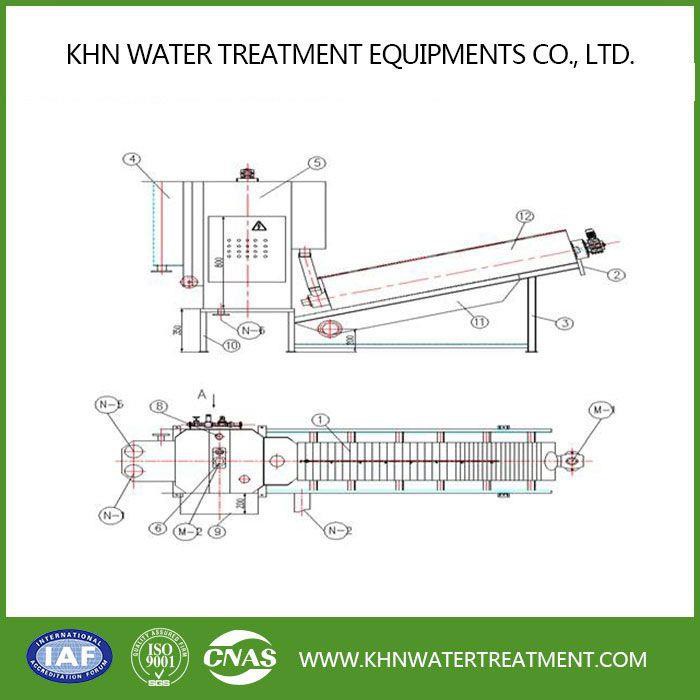

4.Basic principle of structure

The sludge is very easy to stick to the filter cloth of the filter press. It must be removed manually or the high-pressure water pump is used, which consumes a lot of cold water for cleaning. The screw stacker can separate the human mud without touching with the sludge by the actual operators or cleaning with a lot of cold water, which prevents the secondary pollution and ensures the natural environment in the middle of the sludge dehydrator.

The main body of the screw press behavior of the dehydrator is a filtration system which consists of a fixed fixed ring and a traveling ring overlapping each other, and a spiral shaft surrounding the filter system. The front end is the extraction part, and the back sections are the disengaging parts.

The pitch between the fixed ring and the moving ring and the spiral axis is gradually reduced from the extraction part to the detachable part.

The rotation of the screw shaft promotes the sludge transfer from the extraction section to the de drying section, and it also continuously pushes the swam to and fro to clean the filter joint and avoid blocking.

The screw stacker is used in the sludge dehydrator industry in wastewater treatment. Similar to other filter press machines and equipment, it is all the dehydration of physical properties, which must be based on certain preconditions. Therefore, the sludge must be flocculated first, and the floc alum is relatively round and abundant, so the actual effect of sludge output is very good. If the wastewater after flocculation is very clear, then the leakage filtered by the screw stacker will be very good The leach will also be clear, maybe there will be some residue, which is unavoidable. In addition, the situation on the spot is diversified, so the sludge treatment methods of different processes with different characteristics will be different, not the same. All of them must be adjusted continuously.

5.Advantage

1). Environmental protection and energy saving: the main shaft bearing of the stacker needs slow speed ratio, low rated power of the motor, small power consumption, about 40% energy saving compared with the plate frame and belt filter press.

2). It has a long service life. The main body of the screw stacker is made of 304 metal. It has good wear resistance and corrosion resistance. If it is maintained normally, the service life will reach more than ten years.

3). Low maintenance cost, few vulnerable parts and components of the stacker. Unlike the filter press, it is easy to block deformation. It must be removed and replaced frequently. Maintenance cost is low. In addition, the thickness of the wear-resistant layer of the stacker is controlled at 2-3 thicknesses, so that all the machines and equipment are normally used for 5-6 years, so that the wear-resistant layer can be repaired and welded again for more than 5-6 years without removing and replacing the screw shaft, That can greatly reduce the maintenance cost of the application.

After adjustment, the stackable sludge dehydrator is clear about the factory settings after stable operation, and the installation matters that must be paid attention to after arriving at the installation address. First, the installation standard shall be specified. If the grounding device operates, the road surface must be hard bottomed; if the plate spring is necessary, it shall be released and fixed properly. The machinery and equipment shall be installed in the room or be blocked.

Hot Tags: multi disc vertical sludge press filter, China, suppliers, manufacturers, factory, customized, price, OEM