Segment Cover For Rotary Disc Filter

Rotary disc filter is a mechanical sieve that passes liquid through a layer of filter material to take out small particulate matter suspended in the liquid. The filter material used in the filter is woven from various synthetic materials such as metal and chemical fiber in...

Send InquiryIntroduction

Rotary disc filter is a mechanical sieve that passes liquid through a layer of filter material to take out small particulate matter suspended in the liquid. The filter material used in the filter is woven from various synthetic materials such as metal and chemical fiber in different ways. The filter pore diameter is generally 10 ~ 1000um. Mainly used in municipal sewage treatment plant advanced treatment, industrial process water filtration, and reclaimed water reuse. It can replace sand filter and is installed in conventional activated sludge method, SBR system, CASS system, extended aeration method, oxidation ditch system, trickling filter system, oxidation pond system. Adding chemicals can remove part of total phosphorus, turbidity, COD and so on.

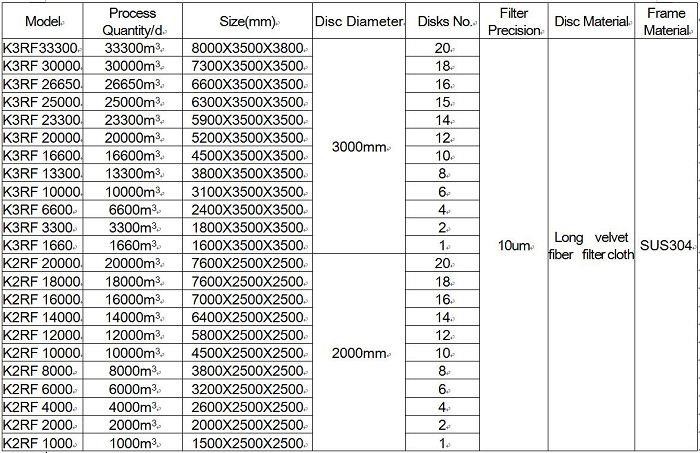

Technical parameters

Product detail

Original: Jiangsu, China

Certification: ISO9001, ISO14001, etc.

Price: Negotiable

Material: SUS304/SUS316

Voltage: 380V 50Hz, the voltage can be as local demand

Payment term: TT, LC

Delivery date: Negotiable

Packing: export standard

Market: Middle East/ Africa/Asia/South America/Europe/North America

Warranty: 1 year

MOQ: 1 set

Equipment characteristics

The operating status of the rotary disc filter includes: static filtration process, negative pressure backwash process, and sludge discharge process.

(1) Static filtration process: The gravity flow of sewage enters the filter tank, and there are baffle energy dissipating facilities in the filter tank. Sewage is filtered through a filter cloth, the filtrate is collected through a hollow tube, and gravity flow is thrown out of the filter tank through an overflow tank. The whole process is continuous.

(2) The negative pressure inversion gradually increases. The height of the water level in the pool is detected by the pressure measuring detection device. When the water level reaches the backwash set value (high water level), the PLC can start the back suction pump and start the backwash process. During backwashing, the filter can be continuously filtered.

During the filtration, the filter disc is in a static state, which is beneficial to the sedimentation of the bottom of the sludge. During backwashing, the filter disc was rotated at a speed of 1 rpm. The suction pump sucks the surface of the filter cloth under negative pressure, sucks up the accumulated sludge particles on the filter cloth, the water in the filter disc is sucked at the same time, and the water plays a cleaning role on the filter cloth from the inside to the outside, and is discharged for backwash To water. The extraction area only accounts for 1% of the total filter plate area, and the backwash process is intermittent.

(3) Draining process: a bucket bottom is set under the filter disc of the fiber turntable filter, which is beneficial to the collection of sludge at the bottom of the pond. The sediment on the bottom of the sludge pool reduces the amount of sludge on the filter cloth, which can extend the filtration time and reduce the amount of backwash water. After a set period of time, the PLC starts the sludge pump and returns the sludge to the sewage pretreatment structure through the sludge drainage pipeline at the bottom of the pond.

Experience and markets:

KHN is professional water treatment equipment manufacturer. Products are well sailed all over the world, got many compliments from customers.

Hot Tags: segment cover for rotary disc filter, China, suppliers, manufacturers, factory, customized, price, OEM