Rotary Vacuum Drum And Disc Filters

Rotary disc filters are widely used in sewage treatment plants. The filter cloth turntable filter has good treatment effect, good effluent water quality, stable effluent water quality, reliable equipment operation and high degree of automation. It is the ideal process...

Send InquiryIntroduction

Rotary disc filters are widely used in sewage treatment plants. The filter cloth turntable filter has good treatment effect, good effluent water quality, stable effluent water quality, reliable equipment operation and high degree of automation. It is the ideal process filtration system equipment for reclaimed water.

Rotary disc filters is mainly used for cooling circulating water treatment and reuse of wastewater after advanced treatment. Used as cooling water and circulating water after filtration: Incoming water quality SS≤60mg / L, Outgoing water quality SS≤10mg / L. It is used for the advanced treatment of sewage. After being installed in the conventional activated sludge method, aeration method, SBR system, oxidation ditch system, and oxidation pond system, it can be used in the following fields: ①Removal of total suspended solids ②Combined with adding agents to remove phosphorus Can remove heavy metals.

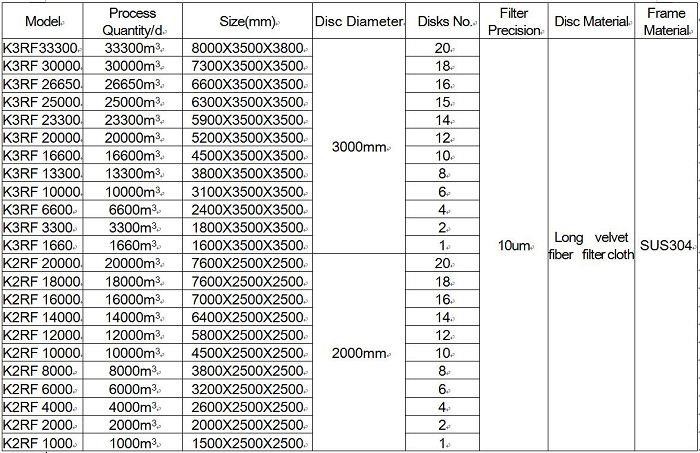

Technical parameters

Product detail

Original: Jiangsu, China

Certification: ISO9001, ISO14001, etc.

Price: Negotiable

Material: SUS304/SUS316

Voltage: 380V 50Hz, the voltage can be as local demand

Payment term: TT, LC

Delivery date: Negotiable

Packing: export standard

Market: Middle East/ Africa/Asia/South America/Europe/North America

Warranty: 1 year

MOQ: 1 set

Equipment characteristics

Rotary disc filters are mainly composed of:

(1) Box, (2) Filter disc, (3) Backwash mechanism, (4) Sludge discharge structure, (5) Central tube, (6) Drive mechanism, (7) Electrical control, (8) Pump, Valve Institutional composition.

1. Box: Welding of carbon steel, imported anticorrosive paint inside, Baotashan epoxy zinc-rich anticorrosive paint for exterior, compact box structure, light weight, small footprint. The auxiliary tank can adjust the water level drop.

2. Filter plate: Each filter plate is composed of 6 independent pieces, covered with filter cloth and substrate. The trap's depth stores trapped particles, reducing head loss during normal operation. Each filter cloth filter disc has at least 5.2m2, 13m2 effective immersion filtering area, and can be easily taken out of the device.

3. Backwashing mechanism: It consists of backwashing suction port, pipeline, backwashing suction port bracket and other components. Used for backwash of filter cloth.

4. Sludge discharge mechanism: It consists of mud suction nozzle, pipeline, mud suction nozzle support parts, etc. Used to clean the sludge from the bottom of the filter.

5. Central tube: After the water is processed, it flows into the auxiliary tank through the hollow tube, and the hollow tube can transport the water and the filter disk can be driven to rotate.

6. Driving mechanism: It consists of reducer, sprocket, chain, etc., which is used to drive the central tube and filter disc to rotate.

7. Electrical system: It is composed of electric control box, PLC, touch screen, liquid level control and other electric control components. It is used to control the process of backwashing and sludge discharge and make it run automatically. .

8. Pump and valve mechanism: It consists of centrifugal pump, pipeline and electric ball valve, which is used for backwashing and sludge discharge.

Experience and markets:

KHN is professional water treatment equipment manufacturer. Products are well sailed all over the world, got many compliments from customers.

Hot Tags: rotary vacuum drum and disc filters, China, suppliers, manufacturers, factory, customized, price, OEM