Disc Vacuum Filter

Fiber rotary filter is one of today's ultra-efficient filters. Good disposal effect, good effluent quality and stable operation.The current mainstream technology of advanced treatment in sewage plant: micro-flocculation reactor + turntable micro-filter treatment + disinfection.

Send InquiryDisc vacuum filterr Introduction

The process cost is low, the operation cost is low, the space in the space is small, and the operation is simple. It is especially suitable for the deep standard upgrading of urban sewage to remove suspended solids SS, CODcr, BOD5 and total phosphorus. It has been proved by practice that the water quality is good, the operation is stable, the operation cost is low, and the operation is simple.

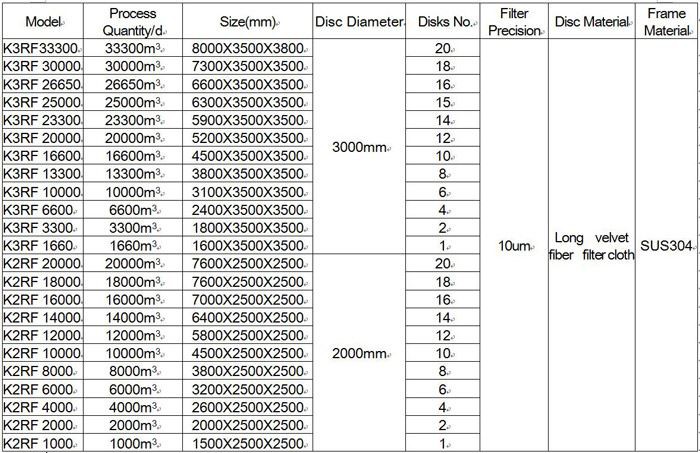

Technical parameters

Product detail

Original: Jiangsu, China

Certification: ISO9001, ISO14001, etc.

Price: Negotiable

Material: SUS304/SUS316

Voltage: 380V 50Hz, the voltage can be as local demand

Payment term: TT, LC

Delivery date: Negotiable

Packing: export standard

Market: Middle East/ Africa/Asia/South America/Europe/North America

Warranty: 1 year

MOQ: 1 set

Equipment characteristics

1. The plan is stable and compact, and the service life is long. It is usually made of 304 stainless steel or 316L stainless steel.

2. The small volume is small (conducive to upgrading projects), which is 75% smaller than the sand filter.

3. The planning is refined, the head loss is small, and the energy consumption is greatly reduced.

4. Simple operation and maintenance, fully automatic operation, no need for special guards.

5. The later capital and operating costs are much lower than other processes.

6. The effluent quality is stable.

The operating conditions of the fiber rotary filter include:

Static filtration process, negative pressure backwash process, and sludge discharge process.

1. Static filtration process: The gravity flow of sewage enters the filter tank, and the filter tank is provided with baffle energy dissipation facilities. The sewage is filtered through the filter cloth, the filtrate is collected through the hollow tube, and the gravity flow exits the filter pool through the overflow tank. The whole process is continuous.

2. The negative pressure reverse position gradually increases. The water level height in the pool is detected by the pressure monitoring device. When the water level reaches the backwash set value (high water level), the PLC can start the back suction pump to start the backwash process. When backwashing, the filter can be continuously filtered.

During filtration, the filter disc is static, which is conducive to sludge sedimentation at the bottom of the tank. During backwashing, the filter disc rotates at a speed of 1 rpm. The suction pump sucks the surface of the filter cloth under negative pressure, and absorbs the sludge particles accumulated on the filter cloth. water. The pumping area only accounts for 1% of the total filter disc area. The backwashing process is intermittent.

3. Sludge discharge process: There is a bucket bottom under the filter plate of the filter tank, which is beneficial to the collection of sludge at the bottom of the tank. Sludge pool bottom deposition reduces the amount of sludge on the filter cloth, which can extend the filtration time and reduce the amount of backwash water. After a set period of time, the PLC starts the sludge pump and returns the sludge to the sewage pretreatment structure through the sludge drainage pipe at the bottom of the tank.

Our Advantages

A. Strict Physical/Chemical testing procedures: meeting the requirements of the product design and process, providing reliable testing data.

B. Short Delivery time: If one container 15-20 days. We also stock some standard-sized tubes and rods, if you need 3-5 pcs, we can delivery soon.

C. Safe packing: anti-rust oil be spread on tubes and rods before shipping, plastic caps on tube ends to protect inside surface, each rod be protected with cardboard tube.

Finally be packed with seaworthy package or in wooden case.

Hot Tags: disc vacuum filter, China, suppliers, manufacturers, factory, customized, price, OEM

Previous

Rotating Vacuum Disc Filter