Continuous Vacuum Filter

After the secondary treatment of urban sewage, it will also contain a considerable amount of pollutants. If this water is discharged into slow-flowing water bodies such as lakes and reservoirs, it will lead to eutrophication of the water body; it will be discharged into water...

Send InquiryContinuous vacuum filter Introduction

If you want to eliminate the above-mentioned effects, you must carry out advanced treatment on this kind of treated water. Filtration is in-depth treatment. At present, there are not many filtration processes used in urban sewage treatment in China, and most of them have the problems of large area, many auxiliary equipment, high operating costs, and difficulty in construction. On the basis of absorption, improvement and innovation, KHN Company changed the traditional filtration concept, and after years of research, it proposed the treatment technology of "fiber rotary disc filter". The process has low capital investment, extremely low operating costs, good effluent quality, and has been tested by practice as an advanced filtration technology.

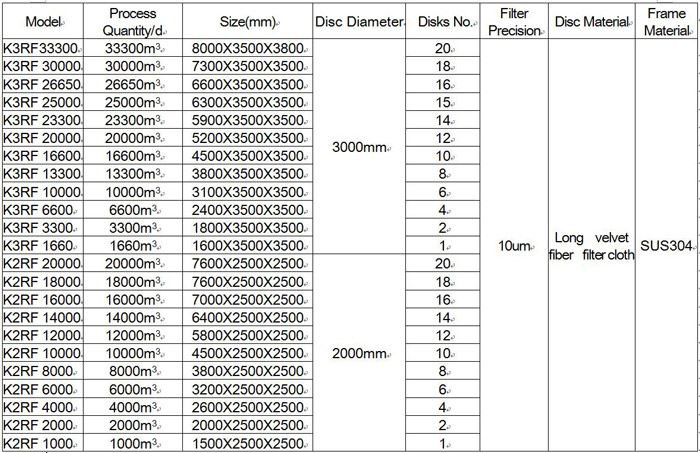

Technical parameters

Product detail

Original: Jiangsu, China

Certification: ISO9001, ISO14001, etc.

Price: Negotiable

Material: SUS304/SUS316

Voltage: 380V 50Hz, the voltage can be as local demand

Payment term: TT, LC

Delivery date: Negotiable

Packing: export standard

Market: Middle East/ Africa/Asia/South America/Europe/North America

Warranty: 1 year

MOQ: 1 set

Equipment characteristics

The fiber rotary filter is composed of a central drum, turntable, backwashing system and supporting control electrical system. The turntable is fixed around the center drum and has a communication hole with the center drum. The raw water (sewage) flows into the drum through the opening at one end of the central drum, and enters each turntable through the communication hole. Filter cloth is installed on both sides of the turntable. The filter cloth is woven of stainless steel wire or polyester wire. 10μm. After the raw water is filtered through the filter cloth, clean water flows out of the filter cloth and is discharged out of the system from the filtered water outlet. As the filtration proceeds, the trapped impurities inside the filter cloth continue to increase, the filtration pressure difference increases accordingly, and the amount of water passing through the filter cloth decreases. When impurities accumulate to a certain degree, the center drum liquid level reaches the set value, and backwashing is required to wash out the impurities accumulated inside the filter cloth. The backwash water pump draws clean water through the filter cloth and sprays it to the outside of the filter cloth to wash off the trapped impurities on the inside of the filter cloth. After washing, the sewage drops into the drip tray and then is discharged outside the device. During backwashing, the turntable rotates and the backwash water sprays filter cloths at different angles until the turntable rotates once. All the filter cloths are cleaned, backwashing stops, and the static filtration process is re-entered until backwashing is performed again.

Product Features

1. The water quality of the fiber rotary filter is good and stable, with SS≤5mg/L and turbidity≤0.5-2NTU;

2. The equipment is simple and compact, the structure is reasonable, the auxiliary equipment is few, and the total installed power is low;

3. The fiber carousel filter is fully automatic and can be continuously filtered without stopping the filtering process during cleaning;

4. The filtering area is large and the floor area is small, which is 5-8 times and 1/3-1/4 of the traditional sand filter tank, respectively, and the project cost is low;

5. The standardization and modular design of the filter assembly of the fiber turntable filter, convenient installation and maintenance, strong expansibility and convenient expansion;

6. Each filter module has its own water outlet, which can monitor the working status of each filter as needed to directly find out the damaged parts;

7. The integrated design of the fiber turntable filter equipment is easy to install and construct;

8. The head loss is small, only 0.05-0.15m;

9. Low energy consumption, the average water consumption per ton is less than 0.0001KWh

10. Low consumption of washing water, the water consumption rate of suction and washing is less than 1%;

11. The fiber rotary filter has strong impact load resistance, and the influent SS can be as high as 40-60mg/L.

Hot Tags: continuous vacuum filter, China, suppliers, manufacturers, factory, customized, price, OEM

Previous

Disc Vacuum Filter