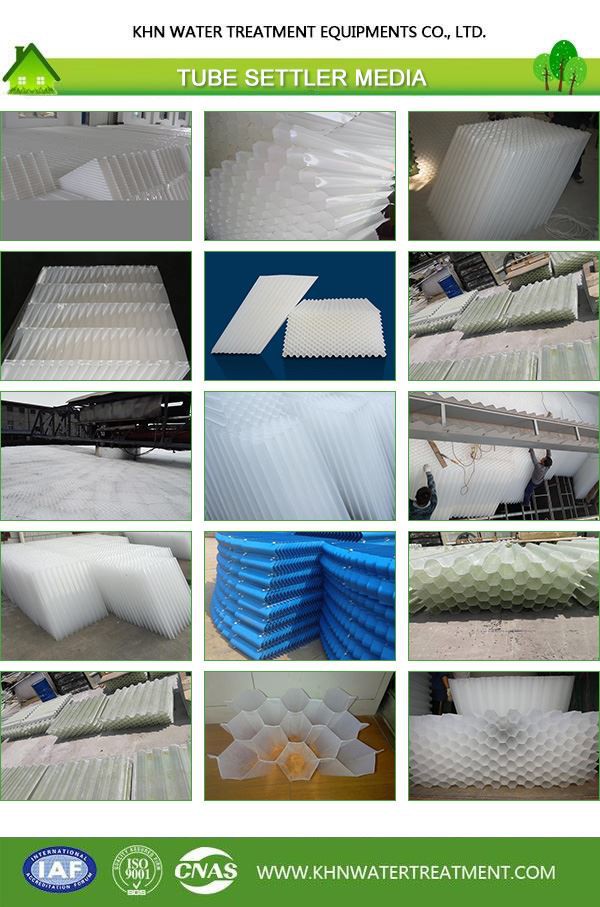

Tube Settler Media

Inclined tube settler media is mainly used for water treatment in water plant sedimentation tank, sewage treatment tank, accelerated sedimentation tank and clarification tank.

Send InquiryIntroduction

Inclined tube settler media is mainly used for water treatment in water plant sedimentation tank, sewage treatment tank, accelerated sedimentation tank and clarification tank. This product has fast sedimentation speed, reduces sedimentation time to improve water production and water purification efficiency, and the quality of the effluent water is good. It is an effective way to tap the potential of water plants and sewage treatment projects.

Product detail

Original: Jiangsu, China

Certification: ISO9001, ISO14001, etc.

Price: Negotiable

Material: SUS304/SUS316L/Q235

Voltage: 380V 50Hz, the voltage can be as local demand

Payment term: TT, LC

Delivery date: Negotiable

Packing: export standard

Market: Middle East/ Africa/Asia/South America/Europe/North America

Warranty: 1 year

MOQ: 1 set

Equipment characteristics

1.Sewage pipe installation at the bottom of sedimentation tank

The installation sequence of the inclined pipe sedimentation tank generally starts from the bottom, and the installation of the lower sludge pipeline system is completed first to ensure that the openings of the sludge pipeline conform to the design.

Inclined tube filler bonding

It is required to be designed and fixed securely, and after the inspection is correct, it is allowed to enter the next installation process.

2.Complete the packing bracket installation

According to the installation construction drawing of the filler bracket of the inclined pipe sedimentation tank, first install the filler bracket in place, check that all welding joints are firm, that the bracket is strong enough to support the weight of the filler, and complete the anticorrosive treatment on the surface of the bracket;

3.Complete the welding of inclined pipe fillers

Pack each inclined pipe filler as a separate welding unit according to the welding method of the inclined pipe filler. One unit is 1m2 after the welding is completed, and it is neatly stacked on the site after the welding is completed (a few scattered pieces are reserved for future use).

4.Assembled in inclined tube packing tank

Assemble the hot-filled packing unit from left to right on the top of the packing bracket. Always keep the angle of 60 ° unchanged. Each unit must be properly compressed when it is assembled sequentially. If the size is not right when assembled to the right side, it needs to be soldered with loose-sheet oblique tube fillers according to the size and assembled until all are in place.

5.The upper part of the inclined pipe packing is fixed

Since the specific gravity of the inclined pipe packing is slightly less than 0.92, the inclined pipe packing needs to be pulled from left to right above the packing after being assembled in place in the pool.

Our Advantages

a. Extensive production experience: we are specialized in it with an experience of 10 years.

b. Complete production facilities: owning precision centerless grinding machine, straightening machine, fine polishing machine, precision lathe, milling and drilling machine, roller press and other advanced equipments. Our technicians will do regular scheduled maintenance on these machines to guarantee them work well.

c. High quality raw material: we mainly choose raw material from big steel factory, such as TPCO, BAO STEEL, SHA STEEL, which are best and largest raw material manufacturer in China.

Hot Tags: Tube Settler Media, China, suppliers, manufacturers, factory, customized, price, OEM