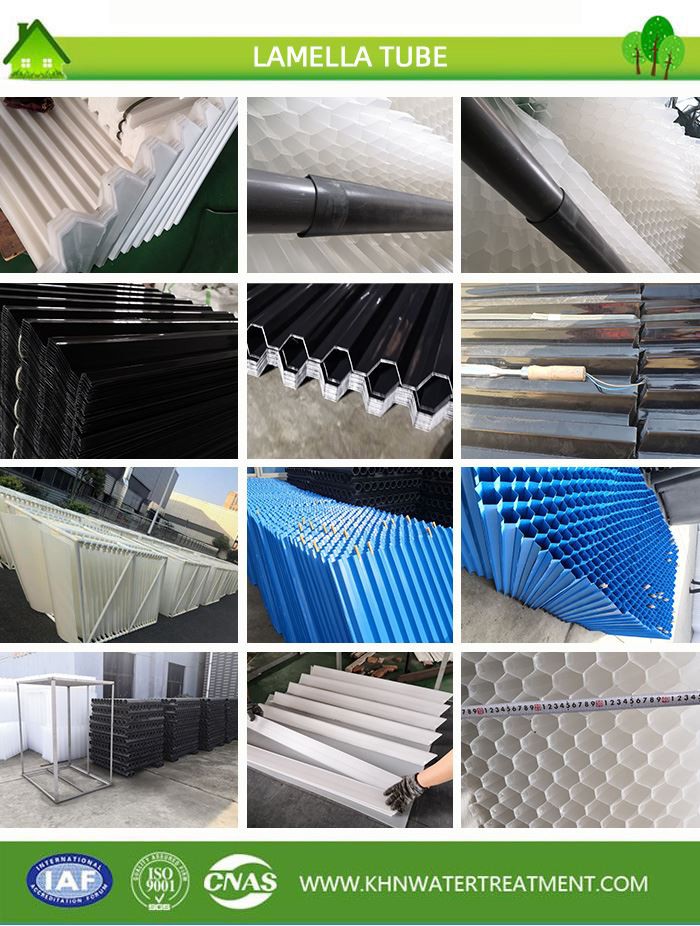

Lamella Tube

Lamella tube used in sewage treatment sedimentation tanks, it has a long service life and low cost, which is twice the service life of the honeycomb inclined pipe. A sedimentation section with reasonable sedimentation distance is set on the upper part of the inclined plate,...

Send InquiryIntroduction

Lamella tube used in sewage treatment sedimentation tanks, it has a long service life and low cost, which is twice the service life of the honeycomb inclined pipe. A sedimentation section with reasonable sedimentation distance is set on the upper part of the inclined plate, and the geometric shape of the inclined plate is controlled at the lower part, so that a stable contact flocculation section is formed at the lower part of the inclined plate, and the purpose of separating alum from water is achieved through contact action and shallow pool sedimentation mechanism. If you're interested in our Lamella tube product, please feel free to contact us.

Product detail

Product Name: Lamella Tube Settler

Original: Jiangsu, China

Certification: ISO9001, ISO14001, etc.

Price: Negotiable

Material: SUS304/SUS316L/Q235

Voltage: 380V 50Hz, the voltage can be as local demand

Payment term: TT, LC

Delivery date: Negotiable

Packing: export standard

Market: Middle East/ Africa/Asia/South America/Europe/North America

Warranty: 1 year

MOQ: 1 set

Hexagonal Honeycomb Inclined Tube Packing

Item | Hexagonal honeycomb inclined tube packing | ||||||||

Material | PP | PVC | FRP | ||||||

Specification mm | φ35 | φ50 | φ80 | φ35 | φ50 | φ80 | φ35 | φ50 | φ80 |

Sheets/m2 | 40 | 30 | 20 | 40 | 30 | 20 | 40 | 30 | 20 |

Sheet thickness mm | 0.40 | 0.45 | 0.60 | 0.35 | 0.45 | 0.65 | 0.3 | 0.5 | 0.7 |

kg/m2 | 18 | 15 | 15 | 31 | 23 | 23 | 41 | 31 | 31 |

Sheet size mm | 1000×1000×δ | 1000×1000×δ | 1000×1000×δ | ||||||

Settler size mm | 1000×1000×866 | 1000×1000×866 | 1000×1000×866 | ||||||

Applications | WTP/WWTP | WTP/WWTP | WTP/WWTP | ||||||

Color | Milky white/black | Sky blue/black | Customized | ||||||

Molding method | Electric soldering iron | Glue | Glue | ||||||

Installation angle | 60° | 60° | 60° | ||||||

Cost | Low | Medium | High | ||||||

Service life | Long | Short | Long | ||||||

Usage frequency | Commonly used | Rarely | less | ||||||

Operating temperature | 5~50℃ | 5~50℃ | 5~70℃ | ||||||

Proportion g/cm3 | 0.92 | 1.35~1.46 | 1.8 | ||||||

Features | Flexible and easy to float | Easy to age, brittle, slightly poisonous | Acid and alkali resistance | ||||||

Produce way | Factory prefab | Factory prefab | Factory prefab | ||||||

standard packaging | Packing strap/wooden box | Packing strap/wooden box | Packing strap/wooden box | ||||||

Special specifications | Customer-defined | Customer-defined | Customer-defined |

Inclined plate packing

PP | PVC | FRP | ||||||

35 | 50 | 80 | 35 | 50 | 80 | 35 | 50 | 80 |

27 | 19 | 12 | 27 | 19 | 12 | 27 | 19 | 12 |

1-2 | 1-2 | 1-2 | 1-2 | 1-2 | 1-2 | 1-2 | 1-2 | 1-2 |

33-66 | 23-46 | 15-30 | 50-100 | 35-70 | 23-46 | 65-130 | 45-90 | 30-60 |

Customer-defined | Customer-defined | Customer-defined | ||||||

Customer-defined | Customer-defined | Customer-defined | ||||||

WTP/WWTP | WTP/WWTP | WTP/WWTP | ||||||

Milky white/black | Sky blue/black | Customized | ||||||

Plastic welding | Plastic welding | Glue | ||||||

60° | 60° | 60° | ||||||

Medium | Low | High | ||||||

Long | Short | Long | ||||||

less | less | less | ||||||

5~50℃ | 5~50℃ | 5~70℃ | ||||||

0.92 | 1.35~1.46 | 1.8 | ||||||

Acid-resistant, alkali-resistant, beautiful | Slightly poisonous | Acid and alkali resistance | ||||||

production on spot | production on spot | Factory prefab | ||||||

Packing strap/wooden box | Packing strap/wooden box | Packing strap/wooden box | ||||||

Customer-defined | Customer-defined | Customer-defined |

Features of Inclined Plate Packing

1. The spacing between the inclined plates is greatly reduced, thereby greatly improving the utilization rate of the sedimentation space.

2. Because the Reynolds number is small, it can effectively suppress and suppress hydraulic pulsation, thereby greatly reducing the negative impact of flow detail disturbance on the settlement of alum blooms.

3. The water distribution is even and no short-flow phenomenon will occur.

4. Due to the structural optimization, the high-efficiency inclined plate precipitation equipment has no lateral constraints, which is more conducive to the sedimentation and separation of alum.

5. The sedimentation area of the inclined plate filler is equal to the sediment discharge area, which is more than 4 times that of the ordinary inclined pipe, which greatly increases the sediment discharge load.

6. Due to the structural characteristics of the high-efficiency inclined plate precipitation equipment, and the thicker specifications of ethylene-propylene copolymer plates and supporting profiles, it has rigidity that cannot be compared with ordinary inclined pipes, resistant to heavy loads, and not easy to deform

Packaging & Delivery

Hot Tags: lamella tube, China, suppliers, manufacturers, factory, customized, price, OEM