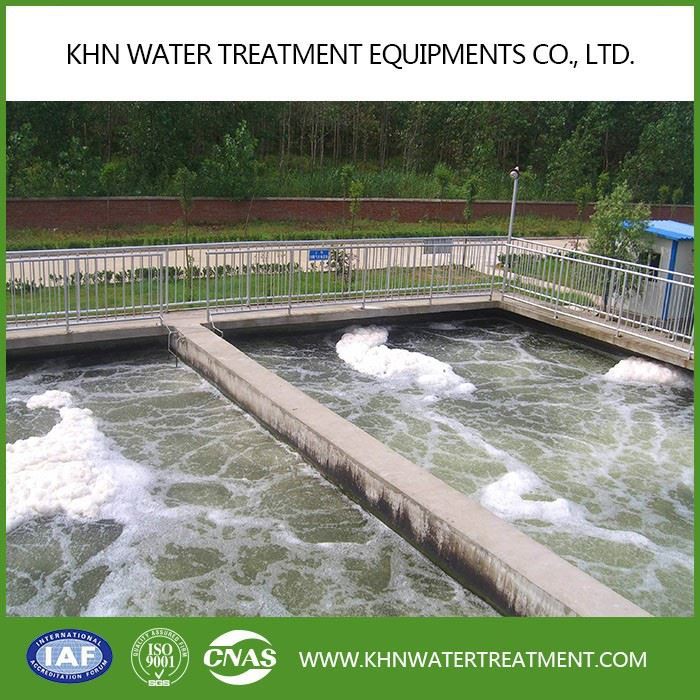

Civil Biological Aerated Filter

Compared with ordinary activated sludge method, biological aerated filter has high organic load, small footprint (1/3 of ordinary activated sludge method), less investment (saving 30%), no It has the advantages of sludge swelling, high oxygen transmission efficiency, and good...

Send InquiryCivil biological aerated filter Introduction

Compared with ordinary activated sludge method, biological aerated filter has high organic load, small footprint (1/3 of ordinary activated sludge method), less investment (saving 30%), no It has the advantages of sludge swelling, high oxygen transmission efficiency, and good effluent water quality [1 ~ 3], but it has stricter requirements for the influent SS (generally requires SS≤100 mg / L, preferably SS≤60mg / L), so Pretreatment of the influent water is required. At the same time, its backwash water volume and head loss are relatively large.

Product detail

Original: Jiangsu, China

Certification: ISO9001, ISO14001, etc.

Price: Negotiable

Payment term: TT, LC

Delivery date: Negotiable

Packing: export standard

Market: Middle East/ Africa/Asia/South America/Europe/North America

Warranty: 1 year

MOQ: 1 set

Equipment Features

The main feature of the aerated biological filter is the use of granular material with a smaller particle size as the filter material. The filter material is immersed in the water, and the blower is used for aeration and oxygen supply. The filter layer plays two roles. First, it acts as a carrier for microorganisms. Compared with a general biological filter, it has a larger specific surface area, and the actual contact time between sewage and biofilms can make the biochemical reaction more thorough. Second, it can be used as a filter medium to trap suspended solids and newly formed biological solids in the water, thereby eliminating secondary sedimentation tanks in other biological treatment methods and obtaining high-quality effluent;

Many bacteria with different properties can grow in the raw aeration filter. In the filter layer closer to the water inlet, the organic content in the sewage is higher, and various heterotrophic bacteria dominate, mainly to remove BOD; in the filter layer closer to the outlet, the organic content in the sewage It is already very low, autotrophic nitrifying bacteria will dominate, and can perform nitrification of ammonia nitrogen. Nitrifying bacteria exist inside the biofilm and have strong adhesion on the filter material. Once formed, it is not easy to completely fall off. Therefore, the aerated biological filter has a strong ability to remove ammonia nitrogen by nitrification.

The horizontal upward flow of gas is used to make the gas and water evenly divided, which prevents the bubbles from condensing and blocking in the filter layer, and the cutting effect of the filter layer on the bubble makes the residence time of the bubble in the filter layer extend Make the utilization rate of oxygen high and energy consumption low;

The upward flow forms a semi-column push condition that is beneficial to the process. Even if high filtration speed and load are used, the BAF process can still guarantee the lasting stability and effectiveness.

Upflow of horizontal air is adopted to make space filtration better used. Air can bring solid materials into the depth of the filter bed, which can maintain high-load uniform solid materials in the filter tank, thereby extending the backwash cycle. , Reducing the amount of water and air used for cleaning.

Working principle

The principle of sewage treatment by aerated biological filter is the oxidative decomposition of microorganisms in the biofilm attached to the filter material in the reactor, the adsorption and retention of the filter material and the microbial film, the grading predation of the food chain formed along the water flow direction, and the interior of the microbial film Denitrification in the microenvironment.

According to the water flow direction in the biological aerated filter, it can be divided into upward flow and downward flow aerated biological filter. Since the upward flow aerated biological filter is close to the ideal filter, it is more widely used in practical engineering. many.

The aerated biological filter reactor is operated periodically, from the start of filtration to the completion of backwashing is a complete cycle. The specific process is as follows:

The pretreated sewage enters the filter layer from the bottom of the filter tank, and an aeration system for oxygen supply is provided at the lower part of the filter layer for aeration, and the gas and water flow in the same direction. In the filter tank, organic matter is oxidized and decomposed by microorganisms, and NH3-N is oxidized to NO3-N; in addition, due to the existence of an anaerobic / anoxic environment in the accumulated filter layer and the inside of the microorganism membrane, part of the nitrification is achieved at the same time Denitrification, the water from the upper part of the filter can be directly discharged from the system.

As the filtration progresses, as the biomass newly generated on the surface of the filter material increases, the SS interception continues to increase. At the beginning, the head loss of the filter tank increases slowly. When the accumulation of solid matter reaches a certain level, the head loss reaches the limit Loss or lead to SS penetration, at this time, the filter tank must be backwashed to remove excess microbial membrane and SS in the filter bed and restore its processing capacity.

The backwashing of the aerated biological filter adopts air-water combined backflushing. The backwashing water is the treated standard water, and the backwashing air comes from the backwashing air pipe under the filter plate. When backwashing, turn off the inlet water and process air, first flush with air separately, then flush with air and water, and finally rinse with water. The filter material layer expands slightly during backwashing. Under the friction between the gas and water erosion of the filter material and the filter material, the aging biofilm and the retained SS are separated from the filter material, and the washed biofilm and SS will reverse The flushing drainage drains out of the filter tank, and the backwashing drainage drains back to the pretreatment system.

Hot Tags: civil biological aerated filter, China, suppliers, manufacturers, factory, customized, price, OEM