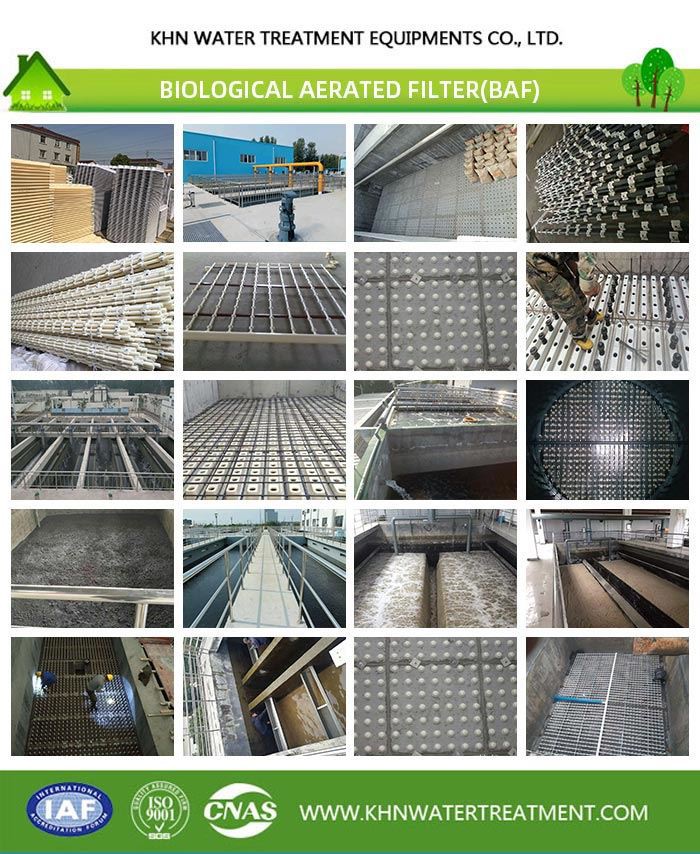

BAF Wastewater Treatment

Biological aerated filter(BAF) belongs to the category of biological treatment biofilm. Biological aerated filter(BAF) is a common process of aerobic biological treatment of wastewater.

Send InquiryBAF wastewater treatment Introduction

Biological aerated filter(BAF) belongs to the category of biological treatment biofilm. Biological aerated filter(BAF) is a common process of aerobic biological treatment of wastewater. Its advantage is that it can increase the load capacity of ordinary filter and strengthen the oxygen supply capacity. The aerated biological filter uses ceramsite filter material with a density greater than that of water as the biological filler. The water flows up and down, and the gas and water are reversed. This process is mainly used for the degradation of organic matter in urban sewage and the removal of ammonia nitrogen.

Product detail

Original: Jiangsu, China

Certification: ISO9001, ISO14001, etc.

Price: Negotiable

Payment term: TT, LC

Delivery date: Negotiable

Packing: export standard

Market: Middle East/ Africa/Asia/South America/Europe/North America

Warranty: 1 year

MOQ: 1 set

Equipment Features

1. BIOCARBONE biological filter

The filter material of the filter is expanded slate or spherical ceramsite with a larger specific gravity than water, and its structure is similar to that of an ordinary fast filter. The pre-treated sewage flows in from the top of the filter tank and flows down from the filter tank. Aeration is performed in the middle and lower parts of the filter tank, and the gas and water are in countercurrent. In the reactor, organic matter is oxidized and decomposed by microorganisms, and NH3-N is oxidized to nitrate nitrogen. In addition, due to the anaerobic / aerobic environment inside the biofilm, partial denitrification can be achieved while nitrification.

If the system does not require N removal, the effluent from the bottom of the filter after treatment can be directly discharged from the system, and part of it can be reserved for backwashing. If there is a requirement for denitrification, the effluent needs to enter the next denitrification filter at the next level, or return to the front denitrification filter at the front, and an external carbon source is needed for denitrification bacteria. In general, the ideal nitrification / denitrification effect cannot be achieved in a single BIOCARBONE filter.

2. BIOSTYR biological filter

The BIOSTYR process is an improvement to its original BIOCARBONE. The filter material is spherical organic particles with a specific gravity of less than 1, floating in water. The pretreated sewage and the nitrified filter effluent are mixed at a certain reflux ratio and enter the bottom of the filter. Aeration is performed in the middle of the filter, and the filter is divided into aerobic and anoxic parts of different volumes according to the degree of denitrification. In the anoxic zone, on the one hand, denitrifying bacteria use the organic matter in the influent as a carbon source to achieve denitrification; on the other hand, the microorganisms on the filter material use dissolved oxygen in the influent and denitrification to generate oxygen to degrade BOD.

At the same time, part of the ss is trapped in the filter bed, which reduces the solid load in the aerobic section. The sewage treated in the anoxic section enters the aerobic section, and the microorganisms in the aerobic section use dissolved oxygen transferred from the air bubbles to the water to further degrade the BOD, nitrification, and removal of ss. The water flowing out of the filter layer is discharged through the upper filter head, and the effluent from the filter tank is discharged into the treatment system except for denitrification and backwash by mixing with the raw water according to the reflux ratio.

3. BIOFOR biological filter

The difference between BIOFOR biological filter and BIOSTRY is the use of filter material with a density greater than water, which naturally accumulates. The filter plate and the special long-handle filter head are under the filter material layer to support the weight of the filter material. The filter head is on top of the filter layer to resist the buoyancy of the filter layer. The rest of BIOFOR's structure, operation mode and functions are basically the same as BIOSTYR

Quality Assurancce

Strict contract auditing invloved all departments to assure the feasibility of each order.

Process design and validation before bulk production.

Strictly control on all raw and auxiliary materials, All raw materials reach the world advanced level.

On-site inspection to all processes, inspection record keep traceable for 3 years.

All inspectors are skilled with international certificates.

Qualified WPS and professional welders guarantee welding quality.

100% inspection of finished sprouts before shipment.

Advanced and complete testing and inspection equipment: NDT, metal Microscope, impact tester, hardness tester...

Regular training for inspection staff.

Hot Tags: baf wastewater treatment, China, suppliers, manufacturers, factory, customized, price, OEM