BAF For Municipal Sewage Treatment

The aerated biological filter(BAF) process is an upstream biological filter. It is a new generation of innovative wastewater treatment process with reliable operation, high degree of automation, good effluent water quality, strong impact resistance and energy saving. The...

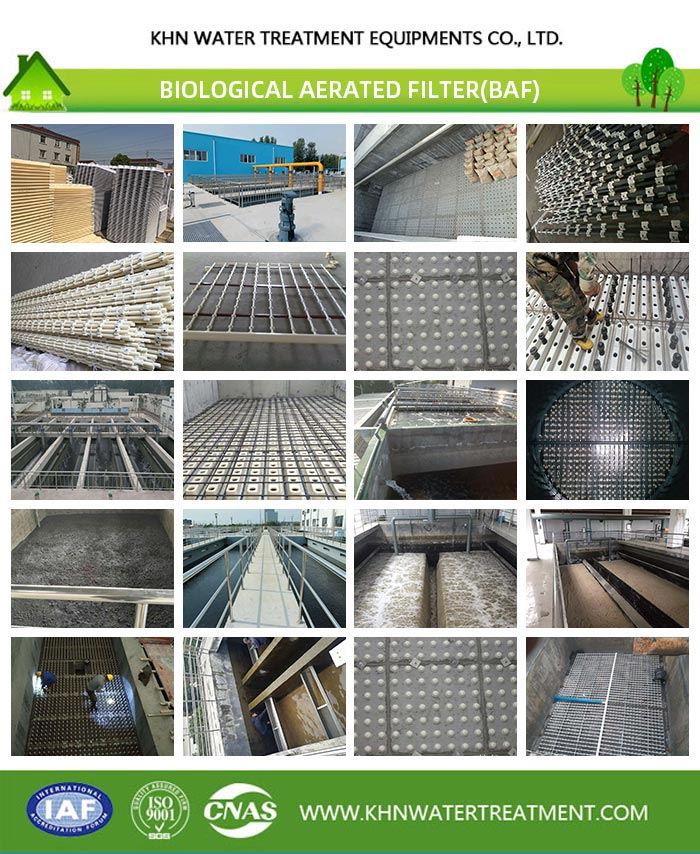

Send InquiryBAF for municipal sewage treatment Introduction

The aerated biological filter(BAF) process is an upstream biological filter. It is a new generation of innovative wastewater treatment process with reliable operation, high degree of automation, good effluent water quality, strong impact resistance and energy saving. The process is mature and efficient.

Product detail

Original: Jiangsu, China

Certification: ISO9001, ISO14001, etc.

Price: Negotiable

Payment term: TT, LC

Delivery date: Negotiable

Packing: export standard

Market: Middle East/ Africa/Asia/South America/Europe/North America

Warranty: 1 year

MOQ: 1 set

Equipment Features

1. Adjust the air supply to the aerated biological filter according to the specific conditions in actual operation, that is, adjust the air intake by controlling the regulating valve of the fan.

2. The biological aerated filter should be controlled by adjusting the hydraulic load, backwash cycle and the amount of biofilm in the filter.

3. The solvent oxygen in the treated water in the biological aerated filter pool should be 4-6mg / L, and the dissolved oxygen at the outlet should be 2mg / L.

4. The transparency of the supernatant of the filter tank, the color, state, and smell of the biofilm on the surface of the filter material should be constantly observed.

5. Abnormal phenomena such as water turbidity and black water quality caused by changes in water temperature, water quality or the operation mode of biological aerated filter, the reasons should be analyzed, and the operating conditions of the system should be adjusted according to the specific situation, and appropriate measures should be taken to make the filter The water quality treatment returned to normal.

6. When the water temperature of the biological aerated filter is low, the method of prolonging the aeration time and reducing the hydraulic load should be adopted to ensure the treatment effect of sewage.

7. When there is scum in the biological aeration tank, the reason should be analyzed according to the color of the foam and the properties of the scum, and the backwash cycle or other corresponding measures should be adjusted to restore it to normal.

8. Since the inlet of the biological aerated filter is the secondary drainage of the urban sewage treatment plant, it is rich in nutrients and can meet the needs of the microorganisms in the pool for their own metabolism; if there is a sudden change in water quality, the lack of nutrients in the water affects the organism For the self-metabolism of microorganisms in the membrane, nutrients can be added to the aeration tank according to the condition of the biofilm. Generally, a nutrient source is added at a ratio of BOD5: N: P = 100: 5: 1. The source of N is urea, and the source of P is sodium phosphate or disodium hydrogen phosphate.

9. When the biofilm of the aerated biological filter grows too fast, the biofilm is too thick or the suspended material in the filter layer is too large, which affects the normal quality of the treated water. Backwash the filter.

Working principle

Sewage passes through the filter layer, the pollutants contained in the water body are intercepted by the filter layer, and are transformed by biodegradation attached to the filter material. At the same time, the dissolved organic matter and specific substances are also removed, and the generated sludge remains in the filter layer In this way, only purified water is allowed to pass, so that complete biological treatment can be achieved in a closed reactor without the need to set up a secondary sedimentation tank downstream for sludge sedimentation.

The bottom of the filter tank is equipped with water inlet and sludge discharge pipes, and the middle and upper part is the filler layer. The thickness is generally 2.5 to 3.5m. To prevent the loss of filter material, a concrete baffle with a filter head is provided above the filter bed. The filter head can be removed from the plate The surface is removed, and the filter bed does not need to be emptied, which is convenient for maintenance. The upper space of the baffle is used as the backwash water storage area, and its height depends on the backwash water head.

In this area, there is a reflux pump for pumping the outlet of the filter tank to the water distribution corridor, and then back to the bottom of the filter tank to achieve denitrification. There is no such reflux system in the process that does not require denitrification. The space between the bottom of the filler layer and the bottom of the filter tank is reserved for the expansion of the filler during backwash regeneration.

The air supply system of the filter tank is divided into two casing paths, and the process air pipe placed in the packing layer is used for process aeration (mainly provided by the aeration fan to provide aeration and aeration), and the packing layer is divided into two areas: the upper part is Aerobic zone, the lower part is anoxic zone. According to different raw water quality, treatment purposes and requirements, the height of the filler layer is different, and the proportion of aerobic zone and anaerobic zone also changes accordingly; the air pipe at the bottom of the filter tank is the backwash air pipe.

Hot Tags: baf for municipal sewage treatment, China, suppliers, manufacturers, factory, customized, price, OEM