Wastewater Treatment Belt Filter Press

The filter press has an air pressure control system that automatically detects the position of the filter belt on the pressure roller and automatically rectifies the deviation.

Send Inquiry1.Wastewater treatment belt filter press introduction

The machine is suitable for sludge dewatering in wastewater treatment processes of municipal wastewater treatment plant, pharmaceutical, electroplating, paper making, leather, printing and dyeing, metallurgy, chemical industry, slaughtering, food, sprinkling manufacturing and environmental protection engineering.

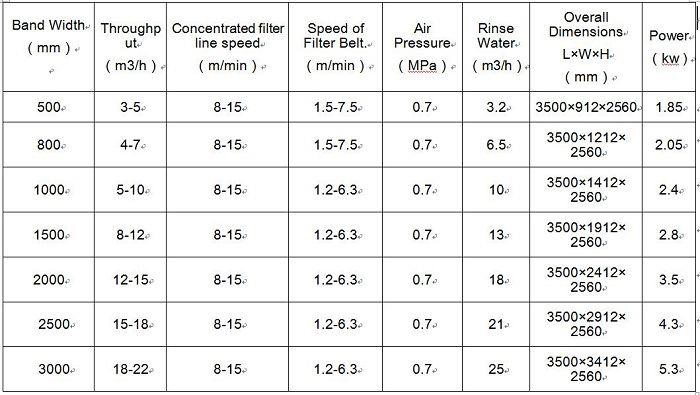

2.Technical parameters

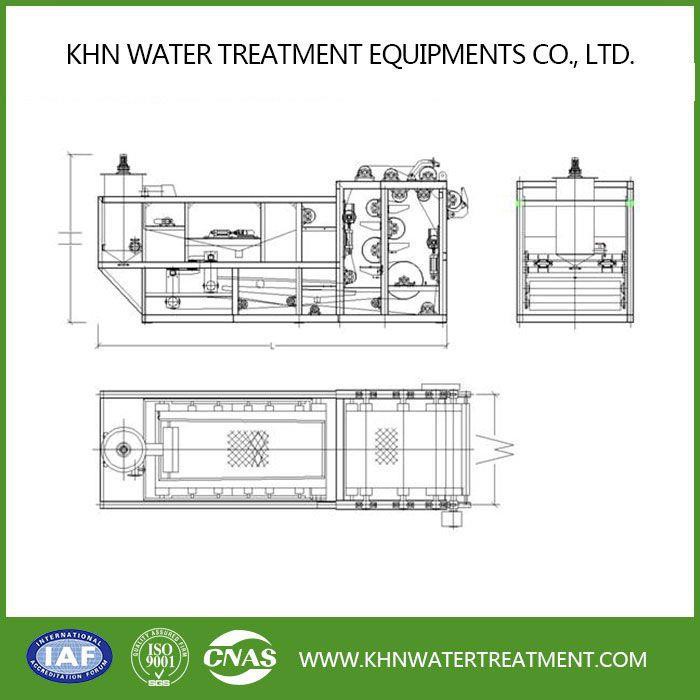

3.Product detail

Original: Jiangsu, China

Certification: ISO9001, ISO14001, etc.

Price: Negotiable

Material: SUS304

Voltage: 380V 50Hz, the voltage can be as local demand

Payment term: TT, LC

Delivery date: Negotiable

Packing: export standard

Market: Middle East/ Africa/Asia/South America/Europe/North America

Warranty: 1 year

MOQ: 1 set

4.Technical performance

Scientific design and reasonable layout ensure that the filter press has high dehydration performance. The filter press has an air pressure control system that automatically detects the position of the filter belt on the pressure roller and automatically rectifies the deviation. For the filter press with wide filter belt, it is not equipped with an automatic sludge feeding device to ensure that sludge enters the filter belt evenly, so as to improve the filtering efficiency and prolong the service life of the filter belt.

5.Working principle

1). Gravity dehydration area

After the sludge pump of the wastewater treatment plant is sent into the sludge mixing tank to mix with polymer coagulant, the fine suspended particles in the sludge are bridged by polymer coagulant to form large particles in the form of latex, and then flow into the subsequent squeezing dehydration operation from the upper end of the mixing tank in the form of gravity flow.

2). Pressure dehydration area

After the sludge enters the pressure dehydration area from the gravity dehydration area, the upper and lower filter cloth begin to squeeze the sludge gradually for dehydration.

3). Pressurized dehydration area

The sludge moves with the filter cloth and enters the pressurized dehydration area. Among the six vertical rollers, the diameter of the rollers decreases from large to small, and the pressure increases from small to large. With the shear force of the upper and lower filter cloth on the sludge caused by changing the upper and lower positions between the rollers, the capillary water in the rubber sludge is squeezed out to produce a dry sludge cake.

Hot Tags: wastewater treatment belt filter press, China, suppliers, manufacturers, factory, customized, price, OEM