Simulation Of Sludge Dewatering On Belt Filters

Sludge belt filter press is a machine that performs mechanical force filtration on the side of the filter medium. It is mainly used for solid-liquid separation of sludge (water). The drive chain of the speed-regulating motor is lubricated once a month to maintain normal...

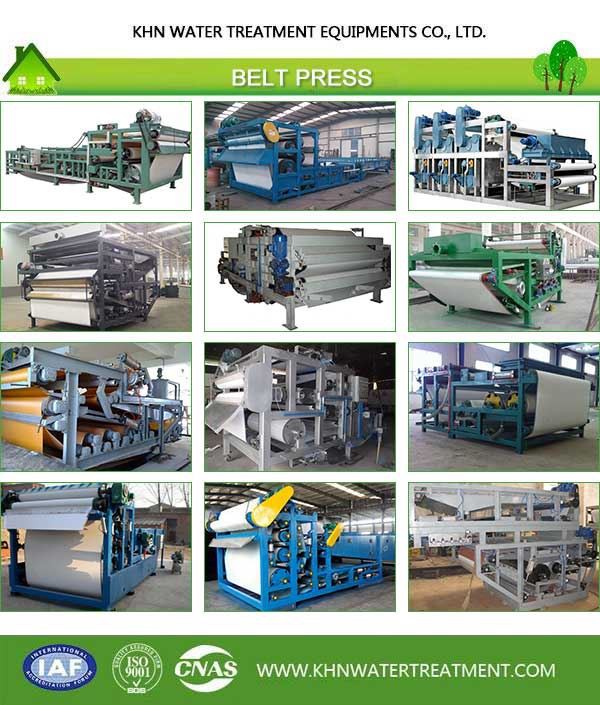

Send InquiryIntroduction

Sludge belt filter press is a machine that performs mechanical force filtration on the side of the filter medium. It is mainly used for solid-liquid separation of sludge (water). The drive chain of the speed-regulating motor is lubricated once a month to maintain normal operation. The sludge filter press is suitable for sludge dewatering in industrial wastewater treatment plants, pharmaceutical, electroplating, papermaking, leather, printing and dyeing, metallurgy, chemical, slaughter, food, brewing and environmental protection. It can also be used in industrial production. In the case of solid-liquid separation, it is ideal for environmental management and resource recovery.

Technical parameters

Product detail

Original: Jiangsu, China

Certification: ISO9001, ISO14001.

Price: Negotiable

Material: SUS304/SUS316

Voltage: 380V 50Hz, the voltage can be as local demand

Payment term: TT, LC

Delivery date: Negotiable

Packing: export standard

Market: Middle East/ Africa/Asia/South America/Europe/North America

Warranty: 1 year

MOQ: 1 set

Equipment characteristics

The working principle of the sludge belt filter press is that the liquid to be filtered passes through the feed pump under a certain pressure, enters the filter chamber from the feed port of the thrust plate, and then passes through the filter cloth. A filter cake is gradually formed; the liquid is discharged from the machine through the water outlet. With the progress of the filtration process, the filter cake begins to filter, the thickness of the mud cake gradually increases, and the filtration resistance increases. When the filter cake reaches a certain thickness or fills the entire frame, the filtration will stop. Open the plate frame, unload the filter cake, clean the filter cloth, reassemble, and then proceed to the next cycle.

The water-containing sludge is transported to the sludge stirring tank by a sludge pump, and a coagulant is added to the mixture for a mixing reaction, and then it flows into the belt-shaped sludge to compact the slurry, and the sludge is evenly distributed in the sludge. The gravity dehydration zone is in a muddy state. Under the action of bidirectional shunting and gravity, as the dewatering filter belt moves, the sludge quickly removes free water from the sludge. Due to the longer design of the gravity dehydration zone, large gravity dehydration can be achieved.

The sludge transformed by the sludge filter press enters an ultra-long wedge-shaped pre-pressure dewatering zone, and the sludge unloaded in the gravity zone is slowly clamped to form a sandwich-type corner layer, and then pre-pressed and pressure-filtered in order to form Sludge layer. The residual free water in the mud layer is reduced to a low level. With the slow progress of the upper and lower filter belts, the up and down distance between the two filter belts gradually decreases, the mud layer in the middle gradually hardens, and the large-diameter filter roll is pre-dehydrated. A large amount of free water is discharged, and the mud cake smoothly enters the extrusion dewatering zone and enters the "S" pressing zone. In the "S" press section, the sludge is sandwiched between the upper and lower layers of the filter cloth. When multiple pressing rollers are repeatedly pressed, and when the upper and lower filter belts are alternately arranged in the wave path formed by interlacing the respective rollers, the shearing force is generated on the sheared mud cake due to the alternating up and down positions of the mud cake being mixed. Two filter belts and remain in the sludge. Most of the water is filtered out, which causes the cake to dehydrate again. The dried mud cake is scraped off by a scraper and conveyed to the sludge storage place by a belt conveyor or a shaftless screw conveyor.

Hot Tags: simulation of sludge dewatering on belt filters, China, suppliers, manufacturers, factory, customized, price, OEM