Belt Press Sludge Dewatering Equipment

The belt type sludge dehydrator is a new type of solid-liquid separation equipment with high efficiency and continuous operation. It uses polyester mesh as filter medium, which can dehydrate all kinds of suspensions with water content below 99.5 through multi-stage pressing...

Send Inquiry1.Belt Press Sludge Dewatering Equipment introduction

The belt type sludge dehydrator is a new type of solid-liquid separation equipment with high efficiency and continuous operation. It uses polyester mesh as filter medium, which can dehydrate all kinds of suspensions with water content below 99.5 through multi-stage pressing into mud cake shape (the water content after dehydration varies with different materials).

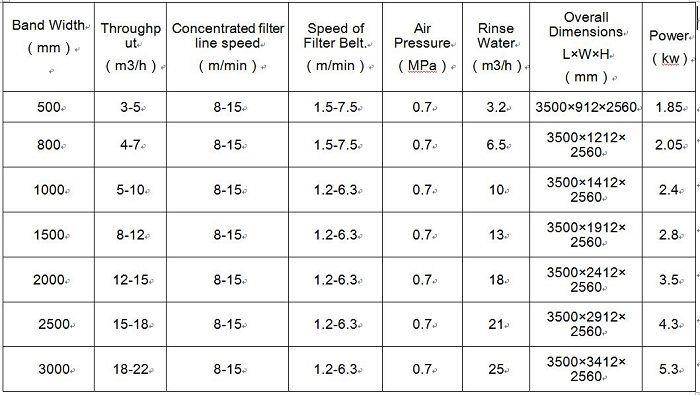

2.Technical parameters

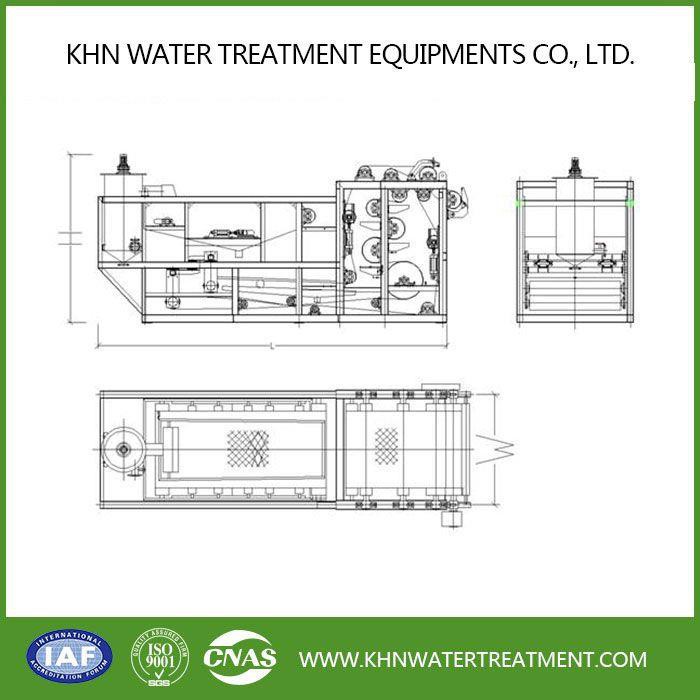

3.Product detail

Original: Jiangsu, China

Certification: ISO9001, ISO14001, etc.

Price: Negotiable

Material: SUS304

Voltage: 380V 50Hz, the voltage can be as local demand

Payment term: TT, LC

Delivery date: Negotiable

Packing: export standard

Market: Middle East/ Africa/Asia/South America/Europe/North America

Warranty: 1 year

MOQ: 1 set

4.Product Advantage

This product is a new generation of belt filter which is developed by our company according to the latest sludge dewatering technology of foreign countries and based on the introduction of models of Klein company of Germany, Andritz company of Austria and emo company of France. (the dosage of this machine can be reduced by more than 20%).

5.Scope of application:

The product is suitable for the dehydration of mixed sludge, digested sludge and surplus activated sludge produced by urban sewage; it is also widely used for the dehydration of various kinds of sludge produced in industries such as gold making, mining, chemical papermaking, printing and dyeing, leather, ferry, brewing, coal, sugar making, etc. Especially for activated sludge, gold making sludge, flotation, concentrate, tailings (coal) dehydration effect is better.

6.Working process

The sludge flows into the feed distributor of the concentration section after fully mixing reaction after adding the coagulant, evenly distributes the sludge to the inclined concentration section, and under the two-way drainage and gravity of the sludge rake, the sludge quickly removes the free water of the sludge with the rotation of the filter belt. After the gravity dehydration, the concentrated sludge is transported to the gravity dehydration section of the belt filter press through the reverse mechanism for further dehydration. Then feed the "s" shaped pressing section. In the "s" shaped pressing section, the sludge is clamped between the upper and the lower two layers of filter cloth, and repeatedly pressed by several different caliber rollers, so that the sludge is dehydrated again. Finally, the mud cake is scraped off by the scraper, and the upper and lower nets are continuously cleaned automatically during the operation.

Hot Tags: belt press sludge dewatering equipment, China, suppliers, manufacturers, factory, customized, price, OEM