Plate Type Fine Bubble Diffuser

Biological treatment methods can be divided into aerobic method and anaerobic method according to the aerobic condition of the microorganisms participating in the effect.

Send Inquiry1.Plate type fine bubble diffuser Introduction

Biological treatment methods can be divided into aerobic method and anaerobic method according to the aerobic condition of the microorganisms participating in the effect. Generally, aerobic method is more suitable for low concentration sewage, such as ethylene plant sewage, while anaerobic method is more suitable for sludge and high concentration sewage. Aerobic biological treatment can be divided into activated sludge process and biofilm process.

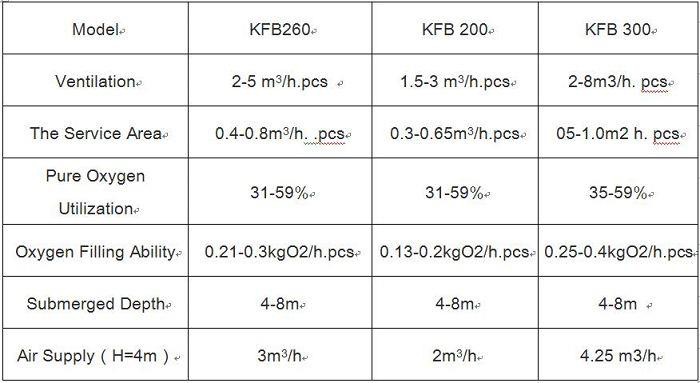

2.Technical parameters

3.Product detail

Original: Jiangsu, China

Certification: ISO9001, ISO14001, etc.

Price: Negotiable

Material: ABS/EPDM

Voltage: 380V 50Hz, the voltage can be as local demand

Payment term: TT, LC

Delivery date: Negotiable

Packing: export standard

Market: Middle East/ Africa/Asia/South America/Europe/North America

Warranty: 1 year

MOQ: 1 set

4.Our Advantages

a. Extensive production experience: we are specialized in Fine Bubble Disc Diffuser with an experience of 10 years.

b. Complete production facilities: owning precision centerless grinding machine, straightening machine, fine polishing machine, precision lathe, milling and drilling machine, roller press and other advanced equipments. Our technicians will do regular scheduled maintenance on these machines to guarantee them work well.

c. High quality raw material: we mainly choose raw material from big steel factory, such as TPCO, BAO STEEL, SHA STEEL, which are best and largest raw material manufacturer in China.

d. Strict Physical/Chemical testing procedures: meeting the requirements of the product design and process, providing reliable testing data.

e. Short Delivery time: If one container 15-20 days. We also stock some standard-sized tubes and rods, if you need 3-5 pcs, we can delivery soon.

f. Safe packing: anti-rust oil be spread on tubes and rods before shipping, plastic caps on tube ends to protect inside surface, each rod be protected with cardboard tube. Finally be packed with seaworthy package or in wooden case.

g. Best after-sale service: Over 60% products are sold to the Southeast Asia, Middle East and Europe, and all products are trusted by domestic and foreign customers.

5.Equipment characteristics

The activated sludge process is an artificial strengthening method for water self purification, which is a method to remove organic matters in sewage relying on the main body of activated sludge operation. It is necessary for aerobic microorganisms in activated sludge to be effective in the presence of oxygen.

In the aeration tank of wastewater treatment biochemical system, there is a positive correlation between aerobic power and aerobic microbial growth. The supply of dissolved oxygen should be based on the quantity, physiological characteristics, matrix properties and concentration of aerobic microorganisms.

In this way, the activated sludge can be in a good state of degradation of organic matter. According to the experiment, it is suitable to keep the dissolved oxygen in the aeration tank at 3-4mg / L. if the oxygen supply is insufficient, the function of activated sludge is poor, which leads to the decrease of wastewater treatment effect. To ensure a satisfactory oxygen supply, it is necessary to rely on a device, such as an aerator.

The gas bubble diameter of the disc aerator is small, the gas-liquid boundary area is large, the bubble diffusion is uniform, there is no hole blockage, and the corrosion resistance is strong. Compared with the conventional products, the energy consumption of the fixed spiral aerator, the diffused aerator and the perforated pipe aerator is reduced by 40%, or the sewage treatment capacity is increased by 40%. It is especially suitable for the construction and expansion of urban sewage and large, medium and small factories, and the reconstruction of old aeration tanks.

6.Cleaning of aeration disk

A. mechanical cleaning

The recommended biological sediment cleaning procedure is to use physical removal of its products, which can be done either by brushing gently or by using a high-pressure water jet cleaner. 1) the distance between the diaphragm and the nozzle should be kept about 50cm to avoid damaging the diaphragm due to excessive water jet flow.

When dephosphorization precipitation is carried out, pure aluminum sulfate and pure iron sulfate shall not be used, and membrane materials shall be treated by chemical methods. The separable strong viscous precipitates are washed off with a high-pressure water jet cleaner.

B. chemical cleaning / OSHA specification msds2)

The common method of chemical cleaning calcium carbonate scale is air flow formic acid detection. With this process, the aeration tank can be drained without any need. Depending on the extent of deposition on the diaphragm surface, the concentrated formic acid (85% by volume) should be added twice a year, putting the commercial grade metering pump into the air stream. Adjust the air flow rate of each aeration plate to the maximum, and add about 100cm3 / 3.4 fl. oz. (liquid ounce) formic acid to each aeration plate within one hour. To subsequently remove formic acid from the system, flush at a constant air flow rate for at least 2 hours.

The exact dosage proportion depends on the degree of deposition, the composition of waste water and the working state. The best dosage needs to be determined by a variety of appropriate methods. Pipe, valve and joint joints must be acid resistant.

Chemicals and additives are not allowed to be used. If chemicals and additives are used, quality assurance commitment will be lost.

1) follow the safety guidelines of the manufacturer of the pressure cleaning mechanism.

2) formic acid is dangerous and may cause serious injury and death. Professional equipment and training of professionals are required. The use of formic acid follows all.

Hot Tags: plate type fine bubble diffuser, China, suppliers, manufacturers, factory, customized, price, OEM