Electrocoagulation Water Treatment

The principle of electrocoagulation water treatment is that aluminum and iron are used as anodes. Under the action of direct current, the anode is dissolved and Al and Fe plasma is produced. After a series of hydrolysis, polymerization and oxidation of ferrous, the...

Send InquiryThe principle of electrocoagulation water treatment is that aluminum and iron are used as anodes. Under the action of direct current, the anode is dissolved and Al and Fe plasma is produced. After a series of hydrolysis, polymerization and oxidation of ferrous, the product reactions develop into various hydroxyl complexes, polynuclear hydroxyl complexes and even hydroxides, which make the colloidal impurities and suspensions in wastewater.

At the same time, the charged pollutant particles swim in the electric field, and part of the charge is neutralized by the electrode, which leads to the destabilization and precipitation.

Original: Jiangsu, China

Certification: ISO9001, ISO14001, etc.

Price: Negotiable

Material: SUS304、aluminum

Voltage: 380V 50Hz, the voltage can be as local demand

Payment term: TT, LC

Delivery date: Negotiable

Packing: export standard

Market: Middle East/ Africa/Asia/South America/Europe/North America

Warranty: 1 year

MOQ: 1 set

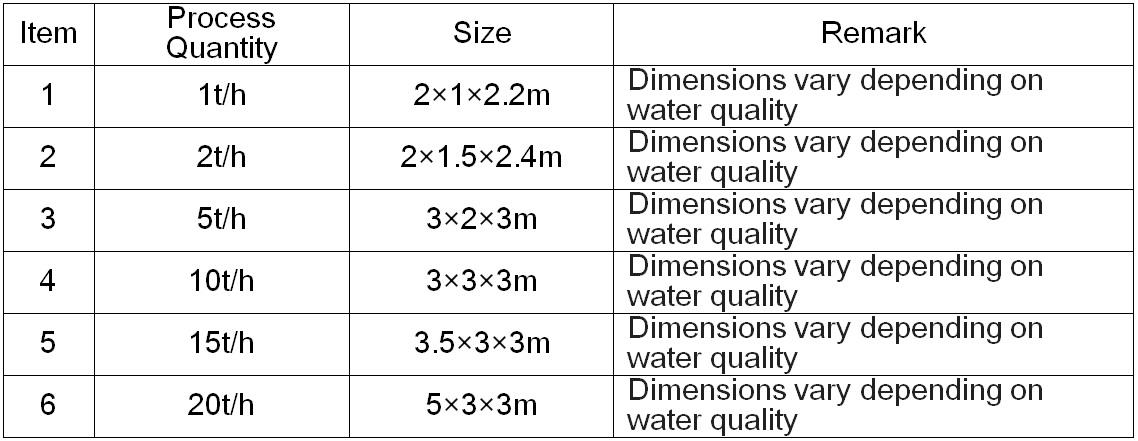

Technical Data

Equipment characteristics

It mainly decomposes and separates the four main functions of electrochemistry: electrolytic oxidation, electrolytic reduction, Electro flocculation, and electrolysis flotation.

1. Electrolytic oxidation

Oxidation during electrolysis can be divided into two categories. One type is direct oxidation, that is, the pollutants lose oxidation directly at the anode and oxidize; the other is indirect oxidation, using an anion with a lower electrode potential in the solution, such as OH-, Cl-, which loses electrons at the anode to generate new ones. Strong oxidant actives such as [O], [OH], Cl2, etc. These active materials are used to oxidize and decompose BOD5, COD, NH3-N and the like in water.

2.Electrolytic reduction

The reduction in the electrolysis process can be divided into two categories. One type is direct reduction, that is, contaminants are directly reduced at the cathode to obtain electrons. The other type is indirect reduction, in which the cations in the contaminants first obtain electrons at the cathode, so that the electrons in the electrolyte at the cathode get electrons directly reduced to low-valent cations or metal precipitates.

3. Electrolytic flocculation

Soluble anodes such as iron, aluminum, etc., after high-voltage pulsed direct current, the anode loses electrons, forming metal cations Fe2+, Al3+, combined with OH- in solution to form highly active flocculating groups, which have strong adsorption capacity and excellent flocculation effect. In the ordinary flocculant, the adsorption and bridging of the waste water can be used to adsorb and remove the pollutants in the wastewater.

4. Electrolysis float

Electrolytic flotation is the electrolysis of wastewater. The ionization of water molecules produces H+ and OH-, and is directed to migrate under the electric field, and hydrogen and oxygen are separated on the surface of the cathode plate and the anode plate, respectively. The newly formed bubbles are very small in diameter, the hydrogen bubbles are about 10 to 30 μm, the oxygen bubbles are about 20 to 60 μm, the diameter of the bubbles (100 to 150 μm) generated when the pressurized dissolved air is floated, and the bubbles generated during mechanical stirring. The diameter (800 ~ 1000μm) should be small. From this, it can be seen that the bubble generated by the electrolysis has higher ability to trap the impurity particles than the latter two, and the dispersion of the bubble is high, and the carrier adheres to the suspended solid in the water, so that the contaminant can be easily removed. Electrolytic air flotation can remove both hydrophobic pollutants in wastewater and hydrophilic pollutants in wastewater.

Experience and markets

KHN is professional electrocoagulation water treatment manufacturer. Products are well sailed all over the world, got many compliments from customers.

Our Advantages

a. Extensive production experience: we are specialized in electrocoagulation water treatment with an experience of 10 years.

b. Complete production facilities: owning precision centerless grinding machine, straightening machine, fine polishing machine, precision lathe, milling and drilling machine, roller press and other advanced equipments. Our technicians will do regular scheduled maintenance on these machines to guarantee them work well.

c. High quality raw material: we mainly choose raw material from big steel factory, such as TPCO, BAO STEEL, SHA STEEL, which are best and largest raw material manufacturer in China.

d. Strict Physical/Chemical testing procedures: meeting the requirements of the product design and process, providing reliable testing data.

e. Short Delivery time: If one container 15-20 days. We also stock some standard-sized tubes and rods, if you need 3-5 pcs, we can delivery soon.

f. Safe packing: anti-rust oil be spread on tubes and rods before shipping, plastic caps on tube ends to protect inside surface, each rod be protected with cardboard tube. Finally be packed with seaworthy package or in wooden case.

g. Best after-sale service: Over 60% products are sold to the Southeast Asia, Middle East and Europe, and all products are trusted by domestic and foreign customers.

Hot Tags: electrocoagulation water treatment, China, suppliers, manufacturers, factory, customized, price, OEM