Electrocoagulation Wastewater Treatment

Electrocoagulation method is a treatment process combining complex adsorption with redox, acid-base neutralization and air-floating separation. The alloy metal such as aluminum and iron is used as the main electrode, and the electrochemical reaction is generated by the...

Send InquiryElectrocoagulation method is a treatment process combining complex adsorption with redox, acid-base neutralization and air-floating separation. The alloy metal such as aluminum and iron is used as the main electrode, and the electrochemical reaction is generated by the application of pulse high voltage. Conversion into chemical energy, at the expense of the anode metal electrode to produce a metal cationic flocculant, separation of pollutants from the water by agglomeration, flotation, reduction and oxidative decomposition, to achieve a technology to purify the water.

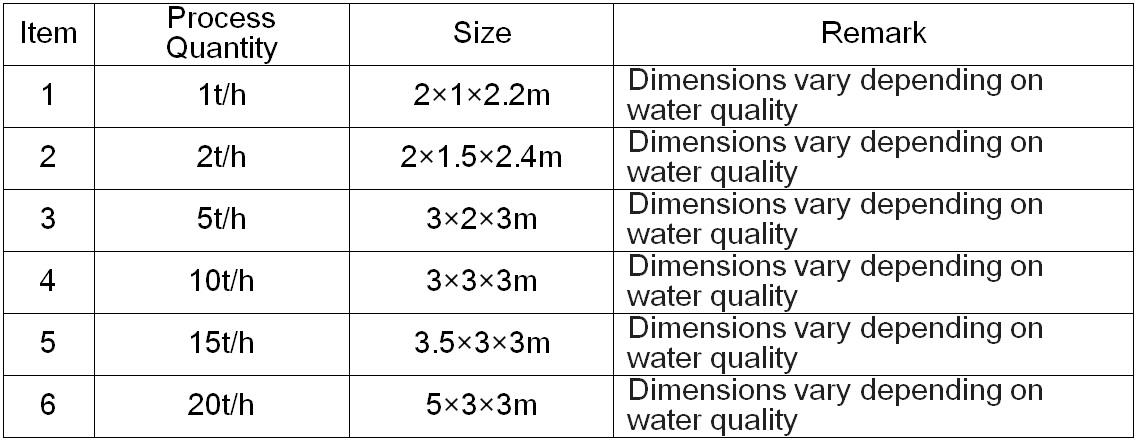

Technical Data

Application

It is applied to wastewater treatment in removing COD, oil, suspended solids, heavy metal ions, color, and refractory organics in water. The main application fields are: Coal chemical wastewater electrocoagulation treatment、University City domestic sewage electrocoagulation、electric phosphorus removal treatment, Oilfield refill hydropower electrocoagulation treatment、Pharmaceutical wastewater electrocoagulation pretreatment、Power plant wastewater electrocoagulation pretreatment、Chemical enterprise electrocoagulation device group、Domestic sewage electric phosphorus removal.

Technical parameters

Original: Jiangsu, China

Certification: ISO9001, ISO14001, etc.

Price: Negotiable

Material: SUS304、aluminum

Voltage: 380V 50Hz, the voltage can be as local demand

Payment term: TT, LC

Delivery date: Negotiable

Packing: export standard

Market: Middle East/ Africa/Asia/South America/Europe/North America

Warranty: 1 year

MOQ: 1 set

Equipment characteristics

1. Low investment costs

2. Low operating costs

3. Low maintenance and repair costs

4, no need to add any chemicals

5. small footprint

6. Solving the problem of traditional electrolytic plate passivation by pulse current

7. Simple operation, high degree of automation

8. Equipment processing time is short, processing efficiency is high

9. Adapt to a wide range of wastewater, can handle a variety of pollutants at the same time

10. Equipment processing produces less sludge, high sludge compaction

The location of electrocoagulation technology in wastewater treatment process

1. Electrocoagulation technology can be pre-treated before the biochemical system. Electroflocculation breaks long chains and chains in sewage by using high voltage, breaks macromolecules into small molecules, thereby improving biodegradability, reducing the load of subsequent biochemical systems and improving the stability of biochemical treatment.

2. Electrocoagulation technology can also be pre-treated before being placed in the water reuse system. Electrocoagulation acts through the high-voltage electric field, breaking the stability of the colloid in the water and precipitating the colloid by flocculation, thereby preventing the subsequent water reuse system due to the presence of colloid in the water, improving the recovery rate and extension of the reclaimed water reuse system. The service life of the membrane tube.

Experience and markets

KHN is professional electrocoagulation wastewater treatment manufacturer. Products are well sailed all over the world, got many compliments from customers.

Our Advantages

a. Extensive production experience: we are specialized in electrocoagulation wastewater treatment with an experience of 10 years.

b. Complete production facilities: owning precision centerless grinding machine, straightening machine, fine polishing machine, precision lathe, milling and drilling machine, roller press and other advanced equipments. Our technicians will do regular scheduled maintenance on these machines to guarantee them work well.

c. High quality raw material: we mainly choose raw material from big steel factory, such as TPCO, BAO STEEL, SHA STEEL, which are best and largest raw material manufacturer in China.

d. Strict Physical/Chemical testing procedures: meeting the requirements of the product design and process, providing reliable testing data.

e. Short Delivery time: If one container 15-20 days. We also stock some standard-sized tubes and rods, if you need 3-5 pcs, we can delivery soon.

f. Safe packing: anti-rust oil be spread on tubes and rods before shipping, plastic caps on tube ends to protect inside surface, each rod be protected with cardboard tube. Finally be packed with seaworthy package or in wooden case.

g. Best after-sale service: Over 60% products are sold to the Southeast Asia, Middle East and Europe, and all products are trusted by domestic and foreign customers.

Hot Tags: electrocoagulation wastewater treatment, China, suppliers, manufacturers, factory, customized, price, OEM