Wastewater Treatment By Electroflocculation

The working principle of the electric flocculation equipment in water treatment is: to connect several groups of parallel plates with direct current, to generate electric field between the plates, so that the water to be treated into the pores of the plates. At this time,...

Send InquiryThe working principle of the electric flocculation equipment in water treatment is: to connect several groups of parallel plates with direct current, to generate electric field between the plates, so that the water to be treated into the pores of the plates. At this time, the electrochemical reaction will take place on the electrified plate, dissolve AL3 + or Fe2 + plasma, and produce flocculation reaction by hydrolysis in water. In this process, electrical floatation, oxygen reduction and other functions will take place simultaneously. As a result, the solubility, colloid and suspended pollutants in water can be effectively transformed and removed.

Original: Jiangsu, China

Certification: ISO9001, ISO14001, etc.

Price: Negotiable

Material: SUS304、aluminum

Voltage: 380V 50Hz, the voltage can be as local demand

Payment term: TT, LC

Delivery date: Negotiable

Packing: export standard

Market: Middle East/ Africa/Asia/South America/Europe/North America

Warranty: 1 year

MOQ: 1 set

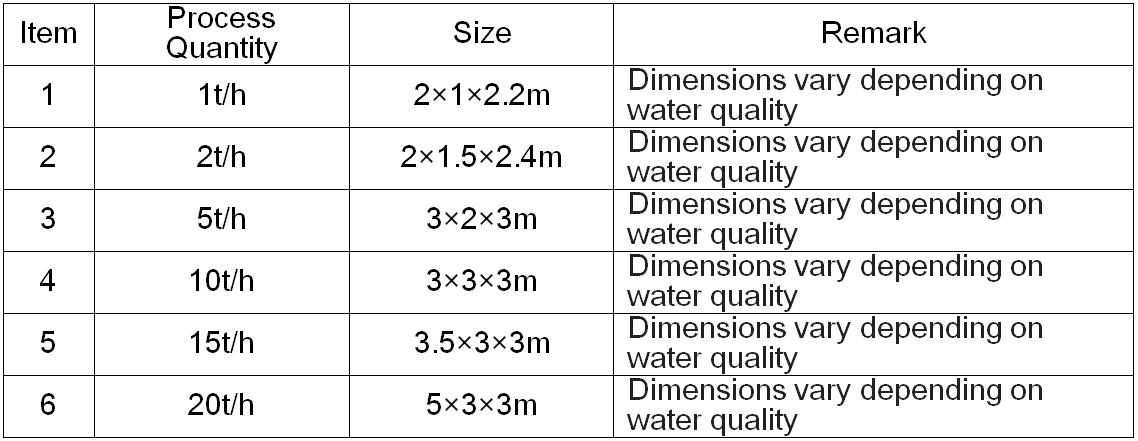

Technical Data

Contaminants and removal effects of electric flocculation in water treatment

The electrode plates of the Electric flocculation equipment in water treatment can be selected according to the different materials to produce strong flocculation, strong oxidation, strong reduction, strong air floatation, etc., in order to achieve the best treatment effect, often used iron, aluminum, titanium , graphite, lead dioxide and so on. Each material has its own application area. The design of electric flocculation equipment in water treatment and the selection of electrode plates are determined through extensive research and development and extensive engineering practice. According to a large number of tests, the effect of electric flocculation equipment in water treatment on the removal of various impurity substances in wastewater is as follows:

1、oil

The removal rate can reach more than 90%. It is verified from practical experience that for the oily wastewater from oil fields and the oily wastewater of oil refineries, the effluent can reach 50mg/L or less in the case of influent oil content of several hundred tens of thousands of mg/L.

2、COD

electric flocculation equipment in water treatment utilizes high-efficiency electrolytic flocculation to produce highly reactive flocculating groups with high adsorptivity. It has a good removal effect on non-soluble macromolecular organics. At the same time, combined with electrical floatation and electro-oxidation, it can further improve the removal rate of organic matter, especially for organic substances that are difficult to biodegrade, can cut chemical bonds by strong oxidation, improve the biodegradability of organic matter, and combine biochemical treatment methods. The purpose of fully degrading COD can be achieved. The electric flocculation equipment in water treatment is aimed at the removal rate of COD. According to different water quality conditions, the removal rate is generally 30%-80%.

3、Heavy metal ions

electric flocculation equipment in water treatment produces OH- ions in water during the process of electrification, and combines iron and manganese ions to form insoluble matter, and then combined with sand filter equipment can effectively remove heavy metal ions in water. The removal rate can reach 80%-95%.

4、Turbidity, suspended matter

Due to its high-efficiency flocculation technology, electric flocculation equipment in water treatment can achieve very good adsorption flocculation for colloidal particles and various impurity particles in water, so that fine particles in water can be aggregated into larger flocs, and the formed floc is more flocculated than flocculation. The floc formed by the agent is larger and denser, thereby facilitating separation of the sedimentation from the water.

electric flocculation equipment in water treatment to treat effluent combined with sedimentation and filtration technology can control the effluent turbidity below 3NTU. If the raw water turbidity is very high (>100NTU), simply change the operating parameters to achieve and treat lower turbidity water. The same flocculation effect. The electric flocculation equipment in water treatment can achieve a turbidity and a removal rate of suspended matter of more than 90%.

Experience and markets

KHN is professional electric flocculation equipment in water treatment manufacturer. Products are well sailed all over the world, got many compliments from customers.

Our Advantages

a. Extensive production experience: we are specialized in electric flocculation equipment in water treatment with an experience of 10 years.

b. Complete production facilities: owning precision centerless grinding machine, straightening machine, fine polishing machine, precision lathe, milling and drilling machine, roller press and other advanced equipments. Our technicians will do regular scheduled maintenance on these machines to guarantee them work well.

c. High quality raw material: we mainly choose raw material from big steel factory, such as TPCO, BAO STEEL, SHA STEEL, which are best and largest raw material manufacturer in China.

d. Strict Physical/Chemical testing procedures: meeting the requirements of the product design and process, providing reliable testing data.

e. Short Delivery time: If one container 15-20 days. We also stock some standard-sized tubes and rods, if you need 3-5 pcs, we can delivery soon.

f. Safe packing: anti-rust oil be spread on tubes and rods before shipping, plastic caps on tube ends to protect inside surface, each rod be protected with cardboard tube. Finally be packed with seaworthy package or in wooden case.

g. Best after-sale service: Over 60% products are sold to the Southeast Asia, Middle East and Europe, and all products are trusted by domestic and foreign customers.

Hot Tags: wastewater treatment by electroflocculation, China, suppliers, manufacturers, factory, customized, price, OEM