BAF For Brewery Wastewater Treatment

The waste water first enters the regulating tank for water quality and quantity regulation, and the effluent from the regulating pool is lifted by the pump and enters the hydrolysis and acidification tank.

Send InquiryBAF for brewery wastewater treatment Introduction

With an annual output of 60,000 tons of beer, the wastewater treatment scale is 2,500t/d.

The waste water first enters the regulating tank for water quality and quantity regulation, and the effluent from the regulating pool is lifted by the pump and enters the hydrolysis and acidification tank. In the hydrolysis acidification tank, the macromolecular organic matter is decomposed into small molecular organic matter easily absorbed by aerobic microorganisms under the action of the hydrolytic acidification bacteria, and the solid organic matter is decomposed into dissolved organic matter, which creates conditions for the subsequent BAF biochemical process. The effluent from the hydrolysis tank is raised to the BAF reactor for the main carbon removal reaction, and the effluent can be discharged to the standard.

Product detail

Original: Jiangsu, China

Certification: ISO9001, ISO14001, etc.

Price: Negotiable

Payment term: TT, LC

Delivery date: Negotiable

Packing: export standard

Market: Middle East/ Africa/Asia/South America/Europe/North America

Warranty: 1 year

MOQ: 1 set

Equipment Features

1. Volumetric load (LV)

Volumetric load (LV) includes BOD5, COD volumetric load and nitrification load. BOD5 volumetric load is generally 2--6 kg BOD5 / (m³.d); COD volumetric load is generally 4--12 kgCOD / (m³.d). The value of volume load is closely related to the quality of influent and effluent water. The higher the volume load of organic matter, the greater the residual concentration of organic matter in the effluent. When the sewage requires that the effluent BOD5 should be 10--20mg / L, Lv can take 3.5-5kg (BOD) 5 / (m³.d);

2. Hydraulic load

The hydraulic load is generally between 3--6m³ / (m³.d), which can be used as the design verification and verification parameters.

3. Biological reaction filter area

The biological reaction filtration area is composed of a biological filtration layer and a supporting layer. The biological filter layer is composed of granular filter material (light ceramsite, anthracite, quartz sand, light plastic particles, etc.). In addition to the requirements for the selection of filter material in addition to particle size, density, porosity, mechanical strength, chemical stability, non-toxic and harmful substances, the most important is the specific surface area. The larger the specific surface area, the more microorganisms grow in the unit filter material, and the higher the biochemical treatment efficiency. The material can be light ceramsite, anthracite, quartz sand, plastic, etc. Judging from the current test and use of various filter materials, lighter ceramsite has more specific surface area (100-400㎡m³) due to its rough surface, well-developed micropores, and strong adsorption capacity. Features, suitable for sewage treatment, therefore, light ceramic particles are mostly used as filter material in biological aerated filter. The diameter of the filter material should be 3--5mm in diameter, the filter layer height is generally 1.5--2., And the filter speed is 0.8--3m / h. The bottom of the biological filter layer is covered with a pebble support layer. Its function is to prevent the filter material of the filter layer from entering the bottom water distribution system and causing loss, and to ensure that the backwash water distribution is uniform. The size of the pebbles gradually increases from top to bottom, and the gas-water backwash system is set in the supporting layer. The supporting layer is recommended to be arranged in three layers of 2--4mm, 4--8mm and 8--16mm, each layer is 50--100mm thick.

4. Backwash

During the operation cycle, with the continuation of time, the gaps in the filter layer are gradually blocked by newly grown biological solids and suspended solids, and the head loss of the filter layer increases. When it reaches a certain level (filter water level 0.3-0.5), it needs to be carried out Backwash. In order to ensure effective flushing, there must be a reasonable water distribution and gas distribution system, and ensure its uniformity. Therefore, the backwashing device adopts a large resistance water distribution system, a uniform gas distribution system, and evenly arranges multiple rows of perforated water distribution pipes and gas distribution pipes in the supporting layer.

5. Aeration system

In order to ensure the normal operation of the biological aerated filter, sufficient aeration needs to be provided to meet the oxygen demand of the biochemical reaction. The removal of organic matter and suspended matter in the sewage, the nitrification of ammonia nitrogen is carried out in the biological filter layer, the amount of oxygen required includes the degradation of organic matter and the nitrification of ammonia nitrogen.

6. Perforation rate of filter head and anti-blocking of filter head

Biological aerated filter often uses a small resistance water distribution system (long handle filter head). Although the inlet water of the filter tank has been pretreated, the suspended matter in it is still more and thicker, especially the viscous materials in the domestic sewage, and the water is mixed with many plastic film fragments, which is very harmful to the filter head. In order to avoid clogging, the filter head gap should be wider than the water supply filter head (2--2.5mm), and the total area of each filter head gap is about 250-350mm square meters. The opening can be larger than the feed water filter, about 0.011-0.015. If the opening ratio is too large, in addition to affecting the backwash uniformity, it also leads to a decrease in the stability of the gas distribution. The diameter of the air distribution hole is 2-2.5mm, and the position should be below the thread of the filter rod or the lower surface of the filter plate is flat. The distance between it and the water distribution bar hole at the lower end of the filter rod should be maintained at 150-200mm or more. The upflow biological aeration filter enters the water from below the filter plate, and once it appears, it is difficult to clean, so in addition to the consideration of the installation of manholes at the low height of the wall pool filter plate, the water level of the filter should be considered when necessary. Relative measures for quickly flushing the filter head from top to bottom to remove the blockage.

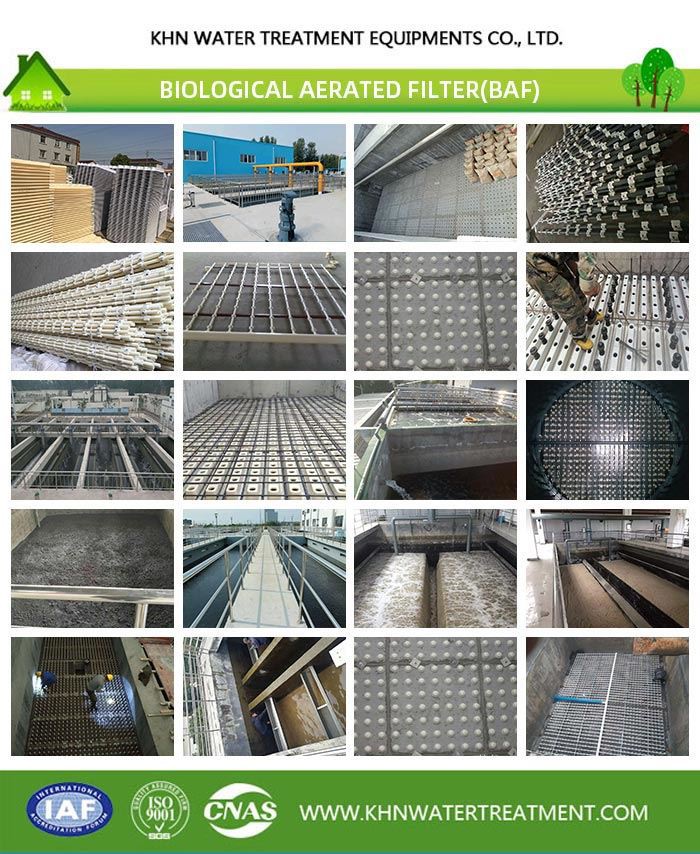

Structural Composition

The aerated biological filter is mainly composed of three parts: biological reaction filter, aeration device and backwash device. Its working principle, calculation method, design parameters (organic load, filtration rate, hydraulic retention time, filter material performance, biological oxygen demand, gas-water backwash strength, etc.), the size of the tank capacity and other factors are determined in the process. The main problem to be solved.

Hot Tags: baf for brewery wastewater treatment, China, suppliers, manufacturers, factory, customized, price, OEM