Stainless Steel Industrial Reverse Osmosis

Reverse osmosis is to separate the solvent (usually water) in the solution through the reverse osmosis membrane (a kind of semi permeable membrane) with sufficient pressure. The direction is opposite to the direction of penetration.

Send Inquiry1.Stainless Steel Industrial Reverse Osmosis Introduction

Reverse osmosis is to separate the solvent (usually water) in the solution through the reverse osmosis membrane (a kind of semi permeable membrane) with sufficient pressure. The direction is opposite to the direction of penetration.

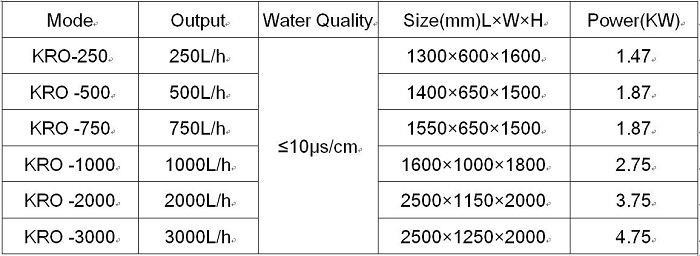

2.Technical parameters

3.Product detail

Original: Jiangsu, China

Certification: ISO9001, ISO14001, etc.

Material: SUS304

Voltage: 380V 50Hz, the voltage can be as local demand

Payment term: TT, LC

Packing: export standard

Market: Middle East/ Africa/Asia/South America/Europe/North America

Warranty: 1 year

MOQ: 1 set

4.Working principle

Reverse Osmosis generally includes pretreatment system, reverse osmosis device, post-processing system, cleaning system and electrical control system.

The pretreatment system usually includes raw water pump, dosing device, sand filter, activated carbon filter, precision filter and so on. Its main function is to reduce the pollution index of raw water and other impurities such as residual chlorine, so as to meet the requirements of reverse osmosis. The equipment configuration of the pretreatment system should be determined according to the specific conditions of raw water.

Industrial Reverse Osmosis Filter mainly includes multi-stage high pressure pump, reverse osmosis membrane element, diaphragm shell (pressure vessel), bracket and so on. Its main function is to remove impurities from the water and make the effluent meet the requirements.

The reverse osmosis method with higher osmotic pressure can be used to separate, purify and concentrate the solution. Using reverse osmosis technology can effectively remove dissolved salts, colloids, bacteria, viruses, bacterial endotoxin and most organic matters and other impurities in water. The main separation object of reverse osmosis membrane is the range of ions in the solution. It does not need chemicals and can effectively remove salt from the water. Generally, the desalination rate of the system is more than 98%. Therefore, reverse osmosis is the most advanced and energy-saving, environmental protection way of desalination, and has become the mainstream pre desalination process.

Advantages of RO reverse osmosis separation process:

Without heating, less energy consumption, continuous and stable operation process, small equipment volume, simple operation, strong adaptability, no pollution to the environment and gradually replace the traditional ion exchange process. The klyro series reverse osmosis device developed by our company is designed with special RO Technology, key components and equipment with famous imported products (such as reverse osmosis membrane of companies such as Hydranautics, dow-filmtec, etc., reverse osmosis membrane shell of companies such as coldline, wavecell, etc., and pressure pump of companies such as groupfos, lowara, nochhi, etc.) Not only advanced technology, but also reliable product quality, strong scalability, reasonable structure, small land occupation, good balance of water utilization rate and product life, low energy consumption, fully automatic operation, simple operation and maintenance.

5.Effluent quality of RO equipment

Reverse osmosis pure water system adopts different processes according to different source water quality. Generally, the conductivity of tap water is less than 10-20 μ s / cm after being treated by the primary RO system, and less than 5 μ s / cm or even lower after being treated by the secondary RO system. After the RO system is supplemented by ion exchange equipment or EDI equipment, ultrapure water can be prepared, making the resistivity as high as 18 megohm. Cm. After the reverse osmosis membrane is aged or polluted, the quality of water produced will decrease

The application of reverse osmosis (membrane separation) technology makes the preparation of ultra pure water from the traditional cation exchanger, decarbonization, anion exchanger, composite ion exchanger and EDI (electrodeionization) technology which has been popularized and applied abroad in recent years. It is a revolution in the manufacturing technology of ultra pure water. Since then, it has entered a super pure water production process without regeneration chemicals, which can produce up to 18m Ω· cm Water is used in semiconductor, integrated circuit and other industries.

Hot Tags: stainless steel industrial reverse osmosis, China, suppliers, manufacturers, factory, customized, price, OEM