RO Mineral Water Plant

RO reverse osmosis technology is the most effective treatment technology for filtering heavy metals. The principle of reverse osmosis is to apply more pressure on the raw water side to reverse osmosis of water molecules from the higher concentration side to the lower...

Send InquiryIntroduction

RO reverse osmosis technology is the most effective treatment technology for filtering heavy metals. The principle of reverse osmosis is to apply more pressure on the raw water side to reverse osmosis of water molecules from the higher concentration side to the lower concentration side. Because the pores of reverse osmosis are far smaller than hundreds or even thousands of times of viruses and bacteria, various viruses, bacteria, heavy metals, solid solubles, and polluted organics cannot pass through the RO reverse osmosis membrane at all, thereby achieving the purpose of purifying water.

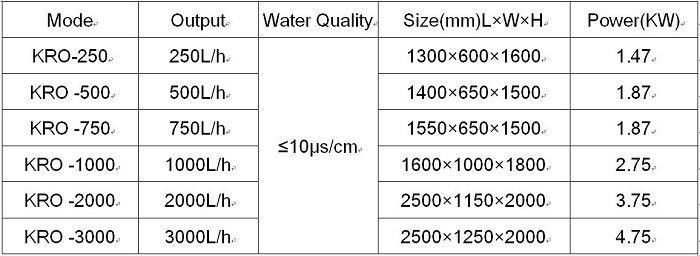

Technical parameters

Product detail

Original: Jiangsu, China

Certification: ISO9001, ISO14001, etc.

Material: SUS304

Voltage: 380V 50Hz, the voltage can be as local demand

Payment term: TT, LC

Packing: export standard

Market: Middle East/ Africa/Asia/South America/Europe/North America

Warranty: 1 year

MOQ: 1 set

Equipment characteristics

1. Regularly inspect and replace the tight filter elements in time to prevent the particles from being contaminated by the reverse osmosis membrane of ultrapure water treatment equipment caused by the leakage of the filter elements due to installation or quality problems.

2. The filters of pure water treatment equipment are regularly backwashed. Compressed air and gas conflicts are held during backwash. After passing the backwash, let it stand for 10 minutes and then wash it forward. After passing the wash water, it can be put into use. Do not bring air into the reverse osmosis membrane.

3. The inlet pressure of the high-pressure pump should be at least greater than 0.05MPa to prevent air or retentate in front of the filter from being drawn into the pure water building reverse osmosis membrane by the high-pressure pump. In order to ensure that the pure water building runs forever, safely, and solidly, it is necessary to do a good job of managing the pure water treatment equipment, timely discover the changes of the operating parameters and mediate the operating conditions of the pure water treatment equipment.

4. Periodically perform test instructions on the quality of water produced by pure water treatment equipment, and adjust the dosage of flocculant, bactericide, reducing agent and scale inhibitor in time according to the actual environment.

5. When compared with the initial commissioning situation, the scale of pure water treatment equipment reverse osmosis device water production drops by 10, or under certain prerequisites, the salinity of the produced water significantly increases, or the pressure difference increases by 15, should respond to reverse osmosis The membrane is rinsed in time.

6. The reverse osmosis membrane of the decommissioned pure water treatment equipment should be washed under low pressure regularly, especially in summer, it should be washed once every shift. If the outage time is more than 7 days, 0.5-1 sodium bisulfite or 0.5-1 formaldehyde solution should be used to protect the reverse osmosis membrane of pure water treatment equipment. The pH value and concentration of the protective solution should be checked in time.

7. The volume of concentrated water should be adjusted in time to maintain a takeover rate of 75. It should neither exercise the concentration of sparingly soluble salt in the concentrated water and cause fouling, but also should not spread the water, that is, it should reach economic operating conditions.

Hot Tags: ro mineral water plant, China, suppliers, manufacturers, factory, customized, price, OEM