High Oxygen Fine Bubble Disc Diffuser

High oxygen fine bubble disc diffuser system is mainly composed of diffuser base, upper screw gland, air equalizing plate, synthetic rubber diaphragm and other components.

Send Inquiry1.High oxygen fine bubble disc diffuser Introduction

High oxygen fine bubble disc diffuser system is mainly composed of diffuser base, upper screw gland, air equalizing plate, synthetic rubber diaphragm and other components. The components are made of engineering plastics. When assembling, the microporous rubber diaphragm should be sleeved on the air equalizing plate and put into the diffuser base with sealing line, and then tightened with upper screw gland.

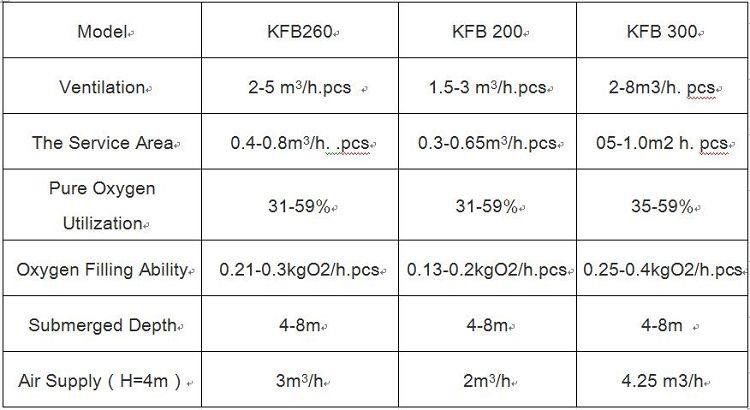

2.Technical parameters

3.Product detail

Original: Jiangsu, China

Certification: ISO9001, ISO14001, etc.

Price: Negotiable

Material: ABS/EPDM

Voltage: 380V 50Hz, the voltage can be as local demand

Payment term: TT, LC

Delivery date: Negotiable

Packing: export standard

Market: Middle East/ Africa/Asia/South America/Europe/North America

Warranty: 1 year

MOQ: 1 set

4.Our Advantages

a. Extensive production experience: we are specialized in Fine Bubble Disc Diffuser with an experience of 10 years.

b. Complete production facilities: owning precision centerless grinding machine, straightening machine, fine polishing machine, precision lathe, milling and drilling machine, roller press and other advanced equipments. Our technicians will do regular scheduled maintenance on these machines to guarantee them work well.

c. High quality raw material: we mainly choose raw material from big steel factory, such as TPCO, BAO STEEL, SHA STEEL, which are best and largest raw material manufacturer in China.

d. Strict Physical/Chemical testing procedures: meeting the requirements of the product design and process, providing reliable testing data.

e. Short Delivery time: If one container 15-20 days. We also stock some standard-sized tubes and rods, if you need 3-5 pcs, we can delivery soon.

f. Safe packing: anti-rust oil be spread on tubes and rods before shipping, plastic caps on tube ends to protect inside surface, each rod be protected with cardboard tube. Finally be packed with seaworthy package or in wooden case.

g. Best after-sale service: Over 60% products are sold to the Southeast Asia, Middle East and Europe, and all products are trusted by domestic and foreign customers.

The air pipe adopts polypropylene or ABS engineering plastic pipe (selected according to the user's needs), on which 3 / 4 internal thread joint is welded, and the microporous aeration head is screwed on the air distribution pipe directly, which is convenient for installation and use, and is conducive to maintenance and repair.

5.Equipment characteristics

The diameter of microporous diffuser is d = 260mm (or 250): type II d = 215mm (or 189). There are 2100-2500 opening and closing holes arranged according to certain rules on the synthetic rubber diaphragm. When air is inflated, the air passes through the air distribution pipe and the air flow equalizing plate, evenly enters between the rubber diaphragms. Under the air pressure force, the diaphragm is slightly bulged and the holes are opened to achieve the purpose of air distribution and diffusion, and the supply is stopped In the case of air, the pressure between the diaphragm and the air equalizing plate decreases gradually, making the orifice close gradually. When the pressure disappears completely, the diaphragm is compacted on the air equalizing plate due to the effect of water pressure and the rebound of the diaphragm itself.

In view of the above structure and the good characteristics of the diaphragm itself, it is impossible for the mixed liquid in the aeration tank to produce backflow, so it will not contaminate the eyelet. On the other hand, when the eyelet is opened, due to the elasticity of the rubber, a small amount of dust in the air will not cause the gap gasifier of the diffuser

The membrane microporous diffuser is generally evenly arranged at the bottom of the aeration tank. According to the introduction of foreign data, the push flow aeration tank is usually arranged in four sections of 35%, 27%, 23% and 15%, which can further optimize the operation and energy saving of the aeration system.

When the membrane microporous diffuser is arranged vertically, the surface of the diffuser is 200mm from the bottom of the tank or the center of the air pipe is 120mm from the bottom of the tank.

The air pipe shall be designed for pressure balance, preferably connected into a ring network. Each group of main pipes shall be provided with valves to facilitate air volume regulation. The design flow rate of air pipe is 15-15m / s for the main pipe. The branch pipe is 5m / s, and the air pipe shall be installed horizontally. When the pipe is laid along the pith and the bottom of the pool, the bracket shall be set for fixation. The air pipe and the air connection shall be connected by rubber hose.

When installing the diffuser, it must be carried out according to the position required by the design. The pipe support shall be used accurately. The steel plate shall be embedded at the bottom of the tank, and the bolt shall be used to connect with the support. The expansion bolt can also be used at the bottom of the tank for fixation.

Hot Tags: high oxygen fine bubble disc diffuser, China, suppliers, manufacturers, factory, customized, price, OEM