Fresh Water Systems

Reverse osmosis pure water equipment is a set of water treatment systems organized around a reverse osmosis membrane. A complete reverse osmosis system consists of a pretreatment system, a reverse osmosis device (membrane filtration part), a post-treatment system, a cleaning...

Send InquiryIntroduction

Reverse osmosis pure water equipment is a set of water treatment systems organized around a reverse osmosis membrane. A complete reverse osmosis system consists of a pretreatment system, a reverse osmosis device (membrane filtration part), a post-treatment system, a cleaning system, and an electrical system. Control system and other components. RO reverse osmosis mainly removes dissolved salts, organics, silica colloids, macromolecular substances and particles that have not been removed in the pretreatment. The two-stage RO process can effectively remove ions in the water, and at the same time, the effluent can meet the subsequent inflow of the EDI device process.

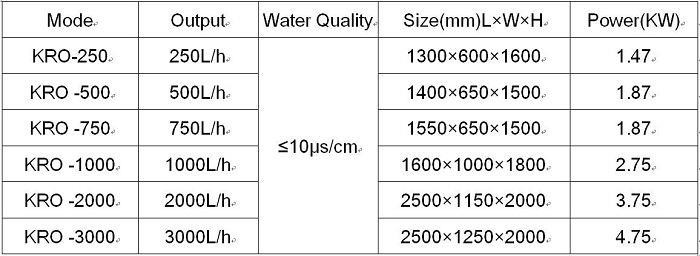

Technical parameters

Product detail

Original: Jiangsu, China

Certification: ISO9001, ISO14001, etc.

Material: SUS304

Voltage: 380V 50Hz, the voltage can be as local demand

Payment term: TT, LC

Packing: export standard

Market: Middle East/ Africa/Asia/South America/Europe/North America

Warranty: 1 year

MOQ: 1 set

Equipment characteristics

The method to prevent microbial contamination is usually to take effective sterilization treatment measures. There are conventional methods such as chlorine gas, NaClO, ClO2, KMnO4, O3, and ultraviolet irradiation. The control is to select a suitable germicidal agent for a sufficient contact time.

For reverse osmosis equipment, complete microbial killing measures must be set up in the pretreatment of reverse osmosis equipment to control the microbial pollution fundamentally.

The method to prevent microbial contamination is usually to take effective sterilization treatment measures. There are conventional methods such as chlorine gas, NaClO, ClO2, KMnO4, O3, and ultraviolet irradiation. The control is to choose a suitable germicide and have a sufficient contact time.

Another is to strictly control the content of organic matter in the feedwater (total organic carbon TOC is not more than 2mg / L), and inhibit the growth of bacteria.

The cleaning of aseptic equipment, especially the sterilization of parts and components directly in contact with medicines, and the date of sterilization, and microbiological verification if necessary. Sterilized equipment should be used within three days.

When the same equipment continuously processes the same sterile product, it should be cleaned and sterilized between each batch; when the same equipment is processed the same non-sterile product, it should be cleaned at least every week or after every three batches

Hot Tags: fresh water systems, China, suppliers, manufacturers, factory, customized, price, OEM