Fine Bubble Membrane Diffuser

1 、 Fine Bubble Membrane Diffuser Introduction Fine bubble membrane diffuser is another new membrane microporous aeration product developed by our company. ABS engineering plastics is used as chassis and tray, and the air distribution film is made of EPDM or silica gel. The...

Send Inquiry1、Product Introduction

The product is another new membrane microporous aeration product developed by our company. ABS engineering plastics is used as chassis and tray, and the air distribution film is made of EPDM or silica gel. The aeration device is composed of aerator, regulator, connector and pipe fittings such as gas distribution pipeline, tee, four-way and elbow.

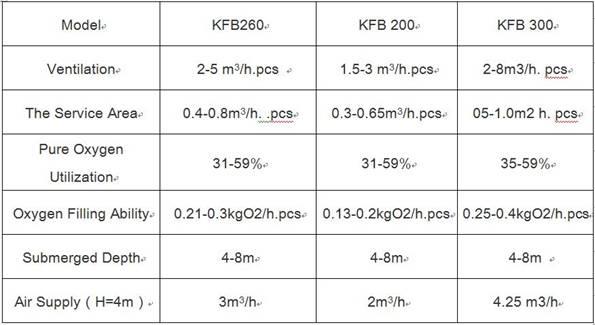

2、Technical Data

3、Product details

Original: Jiangsu, China

Certification: ISO9001, ISO14001, etc.

Price: Negotiable

Payment term: TT, LC

Delivery date: Negotiable

Packing: export standard

Market: Middle East/ Africa/Asia/South America/Europe/North America

Warranty: 1 year

MOQ: 1 set

4、Feature

It is a new type of aeration facility, which can satisfy all aeration tanks, biological contact oxidation tanks, biological stabilization ponds and other places.

The product is arranged according to the air supply and the density of the pool. The aerator and the gas distribution pipeline are connected by G3/4 threads. The base is internal thread (fixed on the gas distribution pipeline), and the aerator is external thread. During installation, the regulator is first fixed to the bottom of the pool, and then the air distribution pipe is fixed to the regulator with a clamp.

The main characteristics are small bubble diameter, uniform bubble diffusion and strong corrosion resistance.

5、Application

The work condition of diffuser is limited to the following conditions

1. Water temperature: 10~50 C

2. Water quality: conventional domestic sewage

3. Water depth: less than 5m

4. Air volume: less than 3m3/h. only.

6、Equipment characteristics

The Fine Bubble Membrane Disc Diffusers adopts the technology of high tech CNC knife opening, which brings three advantages, such as good sealing, tearing resistance, long life and avoiding blocking on surface attachment.

The greatest feature is that in special circumstances need to replace the aerator, do not need to replace the entire aerator, just need to easily replace the diaphragm can greatly reduce the difficulty and cost of late maintenance.

7、Installation sequence

a. Check and install the construction drawings;

b. Check whether the pool size is consistent with the construction drawings.

c. Line drawing according to site conditions and drawings.

d. Expand the bolt by line and install adjustable pipe bracket.

e. Start cutting and blanking according to the size of the drawing.

f. Position the middle intake pipe and bond the matching four-way or three-way connection well (note: must be horizontal and vertical);

g. According to the position of the aerator on the drawings on the branch line, hole size is generally 6-8 mm, according to the specific type of aerator to determine; (After drilling debris must be cleaned up, not left in the pipeline)

h. Put the branch pipe on the adjustable pipe bracket and bond it with the central air intake pipe (note: the hole made on the branch pipe must be vertical upward);

i. The three sides of the two sides of the pipe and the interface of the elbow are bonded with the pipe ends of the branch pipes. (Note: be horizontal and vertical).

j. Adjust the overall level of the pipeline with adjustable pipe bracket.

k. Put the adjustable tube bracket nylon bandage on (Method: Put the side of the nylon bandage without holes into the slot of the bracket, then find a 12 mm iron stick inserted into the square hole of the nylon bandage, and button it gently with a press);

l. Adhesion of aerator nozzles at the position of perforation on the branch pipe (note: aerator nozzles must be vertical upward);

m. The nozzle is firmly bonded (about 24 hours), the aerator will be start installing

After the aerator and pipeline are installed, in order to prevent leakage of the connection of the pipeline, clean water should be put into the tank to the upper part of the aerator about 100 mm, and then ventilation test should be carried out. If the leakage is found, it should be marked and repaired in time. After fully qualified, it can be put into use formally.

8、Experience and markets

KHN is professional Fine bubble membrane diffuser manufacturer. Products are well sailed all over the world, got many compliments from customers.

Hot Tags: fine bubble membrane diffuser, China, suppliers, manufacturers, factory, customized, price, OEM

Previous

Ozone Ceramic Diffusers