Coarse Disc Diffuser

Coarse Disc Diffuser Introduction Coarse disc diffuser uses multi-layer spiral cutting type for aeration. When the air flow enters Disc diffusers, the air flow first passes through two-channel spiral cutting system. After cutting, it enters the multi-layer serrated gas...

Send Inquiry1、Coarse Disc Diffuser/Disc Air Diffuser Introduction

Our product uses multi-layer spiral cutting type for aeration. When the air flow enters Disc diffusers, the air flow first passes through two-channel spiral cutting system. After cutting, it enters the multi-layer serrated gas distributor of the lower layer, and cuts the air bubble into micro-bubbles, thus greatly improving the utilization of oxygen. The utility model has the advantages of uniform gas distribution and high oxygen charging efficiency.

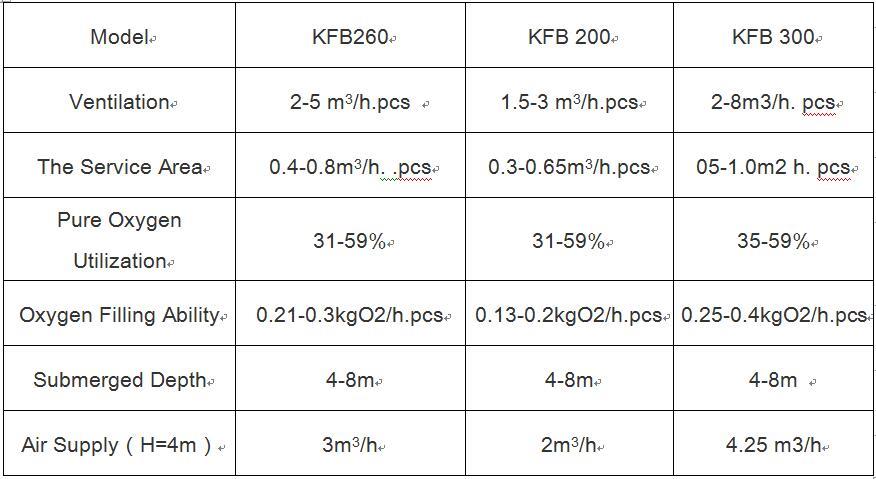

2、Technical Data

3、Product details

Original: Jiangsu, China

Certification: ISO9001, ISO14001, etc.

Price: Negotiable

Payment term: TT, LC

Delivery date: Negotiable

Packing: export standard

Market: Middle East/ Africa/Asia/South America/Europe/North America

Warranty: 1 year

MOQ: 1 set

4、Principle of structure and oxygenation

1. Structure:

1.1. Serrated cloth gas head, the role is to cut dispersed air, diameter D = 100 mm, height H = 120 mm, 18 serrated.

1.2. Sawtooth diffuser cover, diffuser cover design inverted umbrella, the middle circle of the umbrella has 12 aeration holes, play the role of aeration uniform again the whole diffuser cover can reduce energy consumption and water-air mixing uniform shunt, reduce the diffuser installation level requirements. The diffuser is 600 mm in diameter and has 60 downward-sloping serrated teeth around it to further cut the blister.

2. Oxygen charging principle:

As can be seen from the foregoing, the main factors affecting oxygen transfer rate are: flocculation of aerated water, mixing of enterprises, bubble diameter, air volume and partial pressure of oxygen in liquid phase, etc.

The oxygen charging of the type 600 diffuser aerator mainly depends on the following functions:

2.1. Vigorous mixing of liquid gas from the pipeline to the aerator, through the inner hole of φ25 through the serrated cloth gas head, as the water gas cutting for the first time. After the diffuser and the sawtooth cutting, the static water around the diffuser rises, and the gas-liquid mixing is caused by the energy difference. Besides, the bubbles at the bottom of the aerator distribute in the diffuser, convection occurs between the bubbles at the rising bottom and the falling water flow after aeration, and the mixing of gas and liquid is increased, which accelerates the water film renewal at the gas-liquid interface.

2.2. The bubble diameter decreases after two sawtooth cutting and gas-liquid mixing, thus increasing the gas-liquid contact area and facilitating the transfer of oxygen.

2.3. Diffusion effect of diffuser

The diffuser diffuses several kinds of gas beams into cylindrical shape, changes the gas distribution state at the bottom of the tank, enlarges the gas distribution area, and intensifies the bottom bubble diffusion and bottom gas-liquid mixing, which is more conducive to aeration.

5、Application

Coarse Bubble Diffuser uses is suitable for biochemical treatment of large, medium and small industrial wastewater and municipal domestic sewage by activated sludge process, aeration device of biological contact oxidation process wastewater treatment and pre-aeration of regulating pond. It is widely used in push-flow and mixed aeration ponds of biochemical treatment.

6、QUALITY ASSURANCCE

Strict contract auditing invloved all departments to assure the feasibility of each order.

Process design and validation before bulk production.

Strictly control on all raw and auxiliary materials, All raw materials reach the world advanced level.

On-site inspection to all processes, inspection record keep traceable for 3 years.

All inspectors are skilled with international certificates.

Qualified WPS and professional welders guarantee welding quality.

100% inspection of finished sprouts before shipment.

Advanced and complete testing and inspection equipment: NDT, metal Microscope, impact tester, hardness tester...

Regular training for inspection staff

Hot Tags: coarse disc diffuser, disc air diffuser, China, suppliers, manufacturers, factory, customized, price, OEM