Belt Filter Press for Sludge Dewatering

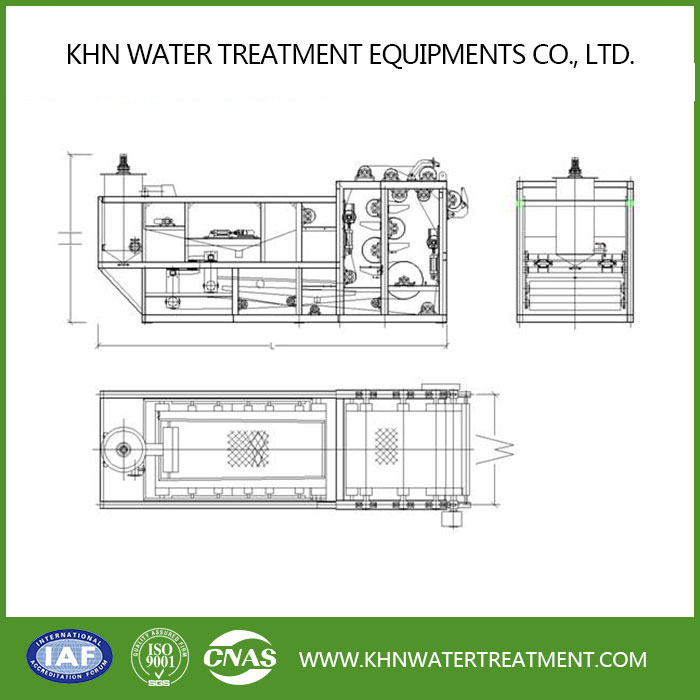

1.The Belt Filter Press for Sludge Dewatering is a solid-liquid separation equipment made from the principle of chemical flocculation contact filtration and mechanical extrusion.

2.After the sludge is mixed with a certain concentration of flocculant in the static and...

1.The Belt Filter Press is a solid-liquid separation equipment made from the principle of chemical flocculation contact filtration and mechanical extrusion.

2.After the sludge is mixed with a certain concentration of flocculant in the static and dynamic mixer, the small solid particles in the sludge are condensed into larger floc mass, and free water and flocculation are separated.

Technical parameters

Product detail

Original: Jiangsu, China

Certification: ISO9001, ISO14001, etc.

Price: Negotiable

Material: SUS304

Voltage: 380V 50Hz, the voltage can be as local demand

Payment term: TT, LC

Delivery date: Negotiable

Packing: export standard

Market: Middle East/ Africa/Asia/South America/Europe/North America

Warranty: 1 year

MOQ: 1 set

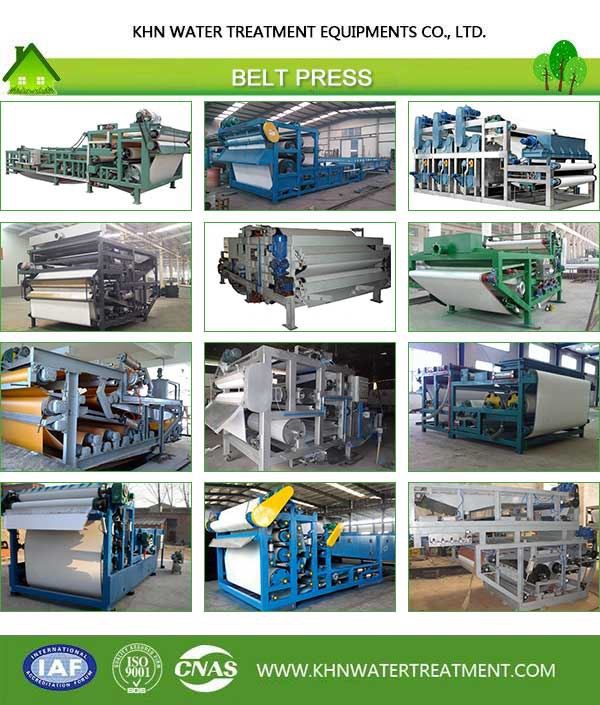

Application

This product is applied to the urban sewage, the textile printing and dyeing, electroplating, papermaking, leather, food processing, mining, coal, petroleum, chemical, chemical, pharmaceutical, ceramics and other industries of Sludge Dewatering, and can also be adapted to the industrialproduction liquid-solid separation or the liquid leaching working procedure.

Equipment characteristics

1.The product adopts the dewatering method of super long filtration and strong force rolling and pressing together. The volume of processing is large, and the moisture content of the filter cake pressed is lower than that of the ordinary machine by 10%.

2. Belt Filter Press adjustment and tension device is advanced and reliable, and pneumatic control is adopted.

3. with high pressure mechanical properties and super corrosion protection capacity, the main part is guaranteed for eight years, and the bearing cots are guaranteed for five years.

4.It can operate continuously for 24 hours, with simple operation and convenient maintenance.

5.After being coagulated, the sludge is transported by gravity and dehydrated on the filter belt. Under the action of gravity, free water is separated to form a sludge which does not flow. Then, between the upper and lower two mesh belts, through the pre pressure area, the low pressure area and the high pressure area are squeezed from small to large. Under the action of shear force, the sludge is squeezed further to reach the maximum degree of mud and water separation. Finally, the filter cake is discharged. It has the advantages of simple process, high automation, continuous operation, simple control operation and adjustable working process.

Our Advantages

a. Extensive production experience: we are specialized in Belt Filter Press with an experience of 10 years.

b. Complete production facilities: owning precision centerless grinding machine, straightening machine, fine polishing machine, precision lathe, milling and drilling machine, roller press and other advanced equipments. Our technicians will do regular scheduled maintenance on these machines to guarantee them work well.

c. High quality raw material: we mainly choose raw material from big steel factory, such as TPCO, BAO STEEL, SHA STEEL, which are best and largest raw material manufacturer in China.

d. Strict Physical/Chemical testing procedures: meeting the requirements of the product design and process, providing reliable testing data.

e. Short Delivery time: If one container 15-20 days. We also stock some standard-sized tubes and rods, if you need 3-5 pcs, we can delivery soon.

f. Safe packing: anti-rust oil be spread on tubes and rods before shipping, plastic caps on tube ends to protect inside surface, each rod be protected with cardboard tube. Finally be packed with seaworthy package or in wooden case.

g. Best after-sale service: Over 60% products are sold to the Southeast Asia, Middle East and Europe, and all products are trusted by domestic and foreign customers.

Hot Tags: belt filter press for sludge dewatering, China, suppliers, manufacturers, factory, customized, price, OEM