Belt Filter Press

The belt filter press has high efficiency, low energy consumption, dehydration, simple structure, convenient maintenance, low noise, stable operation, and reliable continuous automatic production. It is widely used in petroleum, chemical, coal, metallurgy, building materials...

Send InquiryIntroduction

The belt filter press has high efficiency, low energy consumption, dehydration, simple structure, convenient maintenance, low noise, stable operation, and reliable continuous automatic production. It is widely used in petroleum, chemical, coal, metallurgy, building materials and textiles. Solid-liquid separation food and water environmental protection project.

The belt filter press can work continuously and can continuously filter a large amount of sludge. Made of high-strength materials, it has the characteristics of large processing capacity, high dehydration efficiency and long service life. It is widely used in the processing of various industries, and its configured bearings have long service life.

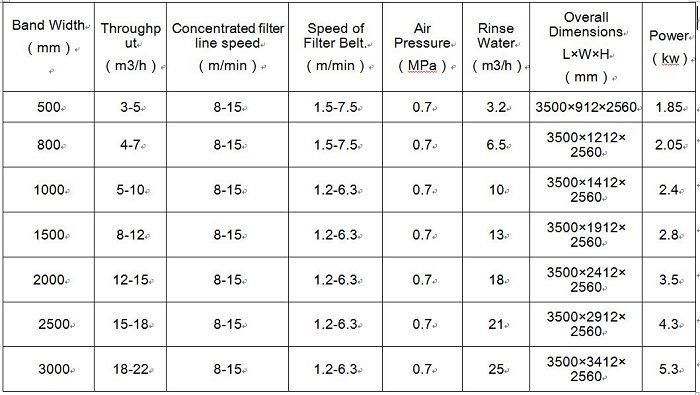

Technical parameters

Product detail

Original: Jiangsu, China

Certification: ISO9001, ISO14001.

Price: Negotiable

Material: SUS304/SUS316

Voltage: 380V 50Hz, the voltage can be as local demand

Payment term: TT, LC

Delivery date: Negotiable

Packing: export standard

Market: Middle East/ Africa/Asia/South America/Europe/North America

Warranty: 1 year

MOQ: 1 set

Equipment characteristics

The belt filter press is composed of two parts: belt concentrated dehydration section and belt press filter section. In order to improve the dehydration of the sludge, improve the properties of the filter cake, increase the permeability of the material, and chemically adjust the sludge. After the sludge is fully mixed and reacted by the flocculation device, it flows into the feed distribution box of the concentration section, and then the sludge is evenly distributed on the inclined concentration section. The main function of the concentration dehydration section is to remove the free water from the material and make the material The reduced liquidity prepares for the next filtration. The sludge is quickly removed by a large number of free water under the action of the mud rake and gravity, as the filter cloth moves. The gravity-dehydrated concentrated sludge is transported to the gravity dehydration zone of the press filter section of the belt filter by the turning mechanism to further dewater. Then enter the "S" type press section. In the "S" type press section, the sludge is sandwiched between the upper and lower layers of filter cloth, and repeatedly pressed by several different caliber rollers, and the mud cake is dewatered again, and then Scrape off the dried cake with a spatula. Each filter cloth is continuously and automatically cleaned throughout the concentrated press filtration stage.

Hot Tags: Belt Filter Press, China, suppliers, manufacturers, factory, customized, price, OEM