Automatic Industry Boiler Water Softener

Boiler softened water equipment, as the name implies, is the equipment to reduce the hardness of water. It is mainly used to remove calcium and magnesium ions in water.

Send Inquiry1.Automatic Industry Boiler Water Softener Introduction

Boiler softened water equipment, as the name implies, is the equipment to reduce the hardness of water. It is mainly used to remove calcium and magnesium ions in water. When the water inlet is deep well water or the hardness of water source is very large, the function of using softened water equipment is to remove the content of calcium and magnesium ions in water, so as to reduce the calcium and magnesium ions in water.

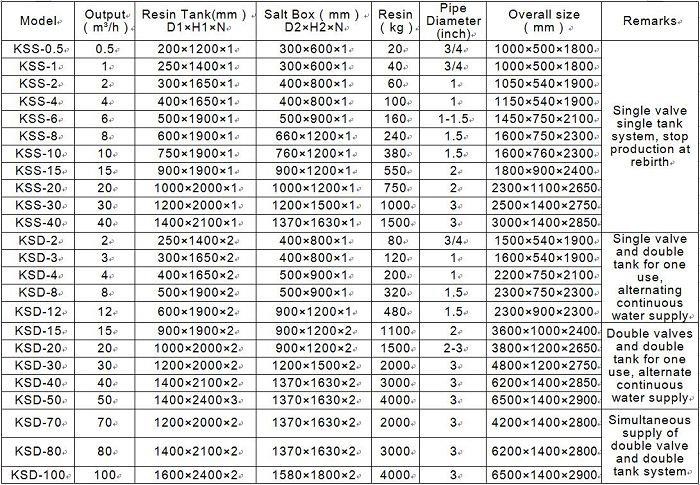

2.Technical parameters

3.Product detail

Original: Jiangsu, China

Certification: ISO9001, ISO14001, etc.

Material: FRP/Q235

Voltage: 380V 50Hz, the voltage can be as local demand

Payment term: TT, LC

Market: Middle East/ Africa/Asia/South America/Europe/North America

Warranty: 1 year

MOQ: 1 set

4.Application

The Water Softener Plant can be widely applied to softening the make-up water of steam boilers, hot water boilers, exchangers, evaporative condensers, air conditioners, direct combustion engines and other systems. It can also be used in the treatment of domestic water, such as hotels, restaurants, office buildings, apartments, home and so on, and the softening water treatment of food, beverage, liquor making, laundry, printing and dyeing, chemical industry, medicine and other industries.

Softened water equipment can not reduce the total salt content of water in the process of softened water. It is widely used in hot water boiler system, heat exchange system, industrial cooling system, central air conditioning system and other water equipment systems.

5.Water softener equipment control mode

Manual type

This method is a traditional standard method, mainly including forward flow / no top pressure and reverse flow. Generally, two tanks with carbon steel structure are connected in parallel. According to different technological processes, each tank needs to be equipped with 8-11 manual valves (two tanks need to be equipped with about 16-20 valves). During regeneration, a special salt pump is used to pump the dissolved salt liquid into the resin tank (this equipment used to be domestic softened water) Main form of equipment). The main characteristics of the softened water equipment of this structure are: the process is easy to understand, easy to operate, low cost, which can be applied to the needs of large flow; however, the technology is backward, the land occupation is large, the operation consumption is large, the actual operation strength is large, the corrosion of the salt pump is heavy and the maintenance cost is high.

Automatic type made in China

Because the use of manual equipment is too complex, in the early 1990s, a new type of equipment with combined integrated valve as the core appeared in China. The main core part of the device is a multi-channel integrated valve, which changes the direction of water flow through the rotation of the valve body. Compared with the traditional manual equipment, this kind of equipment occupies a lot of land and has a high degree of automation. However, due to the time control, the control accuracy is low. Limited by the design idea, processing technology and materials, the plane integrated valve used in most of the equipment is easy to wear, once worn, the possibility of repair is very small. There are many manufacturers of this kind of equipment in the domestic market, the actual quality of products is quite different, and the operation effect of many equipment is not satisfactory.

Fully automatic type produced in Europe and America

In European and American countries, the automation design of ion exchange equipment has been carried out since 1960s. With the development of industrial technology, multi-way valves and integrated valves, which are different from domestic multi-way valves, are gradually developed. The main materials are engineering plastics and lead-free brass. The core component of the valve is a multi-channel integrated valve. Generally, the valve plate or piston is used to control the flow direction, and the small motor drives the camshaft (or piston) to act. Due to the better development of foreign industrial technology, this kind of equipment has developed quite well. The product specifications range from 0.2t/h for domestic use to about 70t / h for industrial use. The controller has a high degree of automation (the latest one can communicate with industrial computer or ordinary monitoring computer).

Discrete valve fully automatic type

In general, the discrete valve is a fully automatic diaphragm valve or solenoid valve, which adopts a structure similar to the traditional manual mode and a special full-automatic controller (single-chip microcomputer or PLC) to form the softened water equipment. The fully automatic equipment is mainly used in the situation of large flow, and can also be used in the transformation of traditional manual equipment. The traditional manual equipment can be transformed into automatic equipment without changing the original equipment pipeline. So as to reduce the operation labor intensity and equipment consumption.

Hot Tags: automatic industry boiler water softener, China, suppliers, manufacturers, factory, customized, price, OEM