Disc Tube Module System

KHN water treatment Co., Ltd. is a professional full-automatic water softening equipment production company, providing boiler water softening equipment; the soft water treatment equipment produced is safe and reliable, and the water softener output is stable and fully meets...

Send InquiryIntroduction

KHN water treatment Co., Ltd. is a professional full-automatic water softening equipment production company, providing boiler water softening equipment; the soft water treatment equipment produced is safe and reliable, and the water softener output is stable and fully meets the design requirements.

Fully automatic water softener equipment. After the process resin fails, it is backwashed with water from bottom to top before regeneration. The purpose of backwashing is twofold. One is to make the resin layer compacted during operation loose by backwashing, which is beneficial for the resin particles to make full contact with the regeneration solution. The first is to make the suspended matter and broken resin accumulated on the resin surface with the backwashing water. Drain, so that the water flow resistance of the exchanger will not increase.

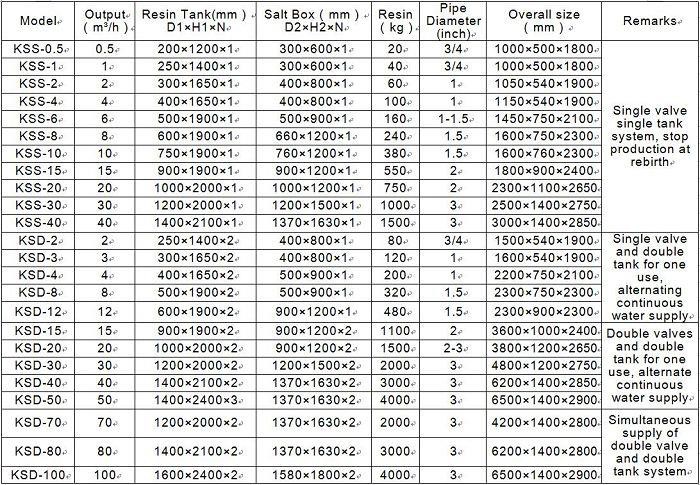

Technical parameters

Product detail

Original: Jiangsu, China

Certification: ISO9001, ISO14001, etc.

Material: FRP/Q235

Voltage: 380V 50Hz, the voltage can be as local demand

Payment term: TT, LC

Market: Middle East/ Africa/Asia/South America/Europe/North America

Warranty: 1 year

MOQ: 1 set

Equipment characteristics

1. The equipment operating cycle and the amount of salt can be adjusted according to the hardness of the raw water. The resin consumption is small, the salt consumption is low, the water quality is excellent, the operation is simple, and the maintenance is convenient.

2. The equipment has strong applicability. For high hardness ≤30mmol/L, the softening residual hardness is less than 0.03mmol/L.

3. Advanced water production technology, adopting floating bed countercurrent regeneration technology, stable water quality and water production, continuous water production, softened hydration salt, regeneration and cleaning. 4. Save salt and water. The specific consumption of recycled salt is 75-90 g/g equivalent, which is far lower than that of similar imported equipment; the self-consumption water is less and only accounts for 2% -4% of the equipment's water production.

4. Long service life. Due to the reasonable design of the valve structure, the service life of the original automatic switch is doubled.

5. The equipment is light in weight, covers a small area, does not require plant buildings, civil construction, and has low installation, operation and maintenance costs.

6. Easy to install, just connect the water pipe and power supply to start the operation. The degree of automation of the equipment is increased, and unmanned operation is realized.

Experience and markets

KHN is professional water treatment equipment manufacturer. Disc Tube Module Systems are well sailed all over the world, got many compliments from customers.

Hot Tags: Disc Tube Module System, China, suppliers, manufacturers, factory, customized, price, OEM