Automatic Industrial Nature Soft Water Softener

Softened water equipment, as the name implies, is the equipment to reduce the hardness of water. It mainly removes calcium and magnesium ions in water.

Send Inquiry1.Automatic Industrial Nature Soft Water Softener Introduction

Softened water equipment, as the name implies, is the equipment to reduce the hardness of water. It mainly removes calcium and magnesium ions in water. In the process of softened water, softened water equipment cannot reduce the total salt content in water.

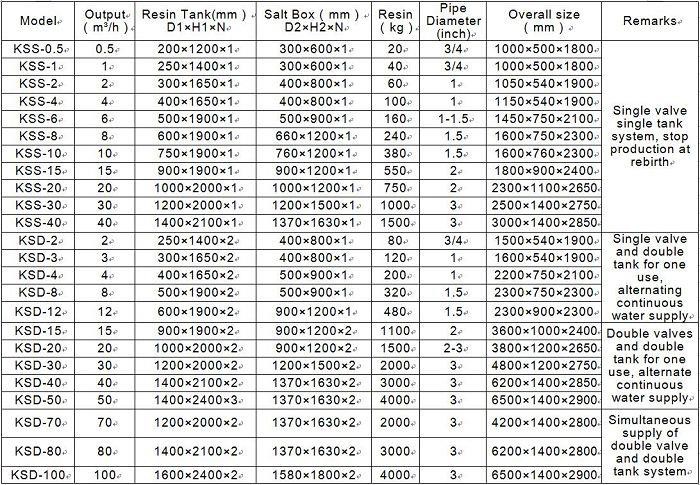

2.Technical parameters

3.Product detail

Original: Jiangsu, China

Certification: ISO9001, ISO14001, etc.

Material: FRP/Q235

Voltage: 380V 50Hz, the voltage can be as local demand

Payment term: TT, LC

Market: Middle East/ Africa/Asia/South America/Europe/North America

Warranty: 1 year

MOQ: 1 set

4.Application

The Water Softener Plant can be widely applied to softening the make-up water of steam boilers, hot water boilers, exchangers, evaporative condensers, air conditioners, direct combustion engines and other systems. It can also be used in the treatment of domestic water, such as hotels, restaurants, office buildings, apartments, home and so on, and the softening water treatment of food, beverage, liquor making, laundry, printing and dyeing, chemical industry, medicine and other industries.

5.Working principle of soft water equipment

As the hardness of water is mainly formed and expressed by calcium and magnesium, cation exchange resin (water softener) is generally used to replace Ca2 + and Mg2 + (the main components forming scale) in water. With the increase of Ca2 + and Mg2 + in resin, the efficiency of removing Ca2 + and Mg2 + of resin decreases gradually.

When the resin absorbs a certain amount of calcium and magnesium ions, it must be regenerated. The regeneration process is to wash the resin layer with salt water in the salt tank, replace the hardness ions on the resin, and discharge the resin out of the tank with the regenerated waste liquid, so that the resin can recover the softening exchange function.

As the hardness of water is mainly formed by calcium and magnesium, the hardness of water is mainly formed by calcium and magnesium, and the principle of sodium ion exchange softening treatment is to exchange the hardness components Ca2 + and Mg2 + in water with Na + in resin through sodium cation exchange resin, so as to absorb Ca2 + and Mg2 + in water and soften water. If RNA is used to represent sodium resin, the exchange process is as follows:

2RNa + Ca2+ = R2Ca + 2Na+

2RNa + Mg2+ = R2Mg + 2Na+

That is, after the water passes through the sodium ion exchanger, the Ca + and Mg + in the water are replaced by Na +.

The operation process of general control valve is as follows: operation, backwashing, salt suction, slow washing, salt tank water supplement, positive washing.

7.The working process of the water softener is generally composed of the following steps:

The regeneration of the full-automatic water softener is started according to the set flow value.

A. Operation (operation) of automatic softening equipment

Under a certain pressure (0.20-0.6mpa) and flow, the raw water enters the container (resin tank) containing ion exchange resin through the valve chamber of the controller. The Na + contained in the resin and the cations (Ca2 +, Mg2 +, Fe2 +) in the water Through the exchange, the content of Ca2 +, Mg2 + ions in the outlet water of the container can reach the established requirements, and the hard water can be softened.

B. Backwashing of automatic softening equipment

After resin failure, backwash with water from bottom to top before regeneration. There are two purposes of backwashing: one is to loosen the compacted resin layer during operation through backwashing, which is conducive to the full contact between resin particles and regeneration liquid; the other is to make the suspended solids and broken resin accumulated on the resin surface discharge with backwashing water, so that the water flow resistance of the exchanger will not increase.

C. Regeneration and salt absorption of fully automatic softening equipment

Under a certain concentration and flow rate, the regenerated salt liquid flows through the failed resin layer to restore its original exchange capacity.

D. Automatic softening equipment replacement (slow cleaning)

After the regeneration liquid is fed into the exchanger, there are still salt liquid not involved in the regeneration exchange. Clean with clean water less than or equal to the flow rate of the regeneration liquid (slow cleaning), so as to make full use of the regeneration effect of the salt liquid and reduce the washing load.

E. Full automatic softening equipment washing (rapid cleaning)

The purpose is to remove the residual regeneration waste liquid in the resin layer, usually at a normal flow rate until the effluent is qualified.

F. Full automatic softening equipment regenerant tank water injection

Fill the regenerant tank with water with the amount of salt required for one solution regeneration.

Hot Tags: automatic industrial nature soft water softener, China, suppliers, manufacturers, factory, customized, price, OEM