Rotating Sludge Scraper

The sludge scraper is an ideal supporting equipment for the sedimentation tank in the process of sewage treatment by the activated sludge method, which is suitable for the primary sedimentation tank or the secondary sedimentation tank.

Send InquiryIntroduction

TheRotating Sludge Scraper is an ideal supporting equipment for the sedimentation tank in the process of sewage treatment by the activated sludge method, which is suitable for the primary sedimentation tank or the secondary sedimentation tank. Its main function is to remove the sludge settled in the sedimentation tank and the floating substances on the surface of the water surface. It is generally applicable to large and medium-sized sedimentation tanks. Double peripheral transmission, large transmission torque, the central support and rotating truss are connected in the form of hinge. When the torque generated by the mud scraper acts on the central support, it is converted into the peripheral friction force of the central rotating bearing, so the stress conditions are good, the center water inlet, sludge discharge, peripheral water outlet, and the agitation of the water body is small, which is conducive to sludge cleaning.

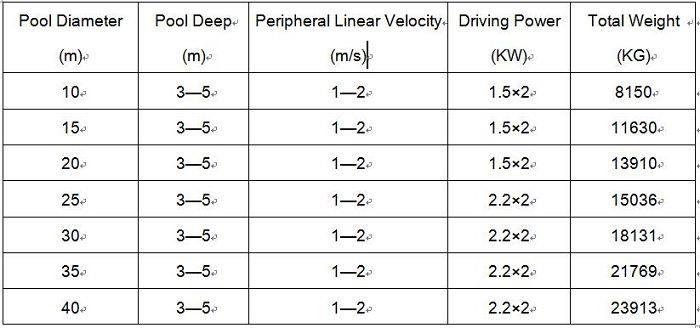

Technical parameters

Product detail

Original: Jiangsu, China

Certification: ISO9001, ISO14001, etc.

Price: Negotiable

Material: SUS304/Q235

Voltage: 380V 50Hz, the voltage can be as local demand

Payment term: TT, LC

Delivery date: Negotiable

Packing: export standard

Market: Middle East/ Africa/Asia/South America/Europe/North America

Warranty: 1 year

MOQ: 1 set

Equipment characteristics

The Rotating Sludge Scraper is mainly composed of full bridge working bridge (including walkway and escalator), driving device, mud collecting tank, mud suction device, vacuum pumping and siphon destruction system, rotating and fixed mechanism, scraper assembly, skimming mechanism, slag hopper combination, outlet weir cleaning brush, control cabinet and connecting fastener, spare parts, etc.

The working bridge is made of galvanized steel welded into truss structure. The working bridge is paved with steel galvanized grid walkway plate, with a width of 1000mm and a total width of 1200mm. The working bridge has rigidity and strength, can bear * large mud scraping torque, can also bear the weight of suspension equipment and 300kg / m2 active load, the * large deflection of the working bridge is controlled within 1 / 180 of the pool diameter.

The working bridge is a full bridge with the length meeting the requirements of the inner diameter of the Φ 30m pool. There are railings and lifting lugs on the working bridge and ladders on both ends of the working bridge. The design and manufacture of the whole bridge are solid, light and beautiful.

An emergency stop button is set at the end of the working bridge to observe the operation of the equipment and facilitate the control of the operator nearby.

All joints and welds of the working bridge shall be flat and smooth, and the weld strength shall be greater than that of the base metal. The overall appearance of the bridge shall be beautiful.

Rotating Sludge Scraper is driven by single periphery and installed at the end of working bridge pool. The driving device mainly includes end beam, drive reducer, motor, over torque limiting device, cleaning device, traveling wheel, transmission shaft, bearing seat and other parts. The driving device has strength and torque to meet the traction of suction dredger, and the driving device can adapt to continuous work 24 hours a day. The linear speed around the bridge is 2 .5m/min.

End beam: the end beam is made of carbon steel section steel. The guaranteed rigidity and strength bear the force when the equipment is running. The structure is simple and easy to install and maintain the walking wheel.

Drive reducer and motor: the drive reducer and motor are all sew products from Germany. The reducer is shaft mounted and directly connected to the traveling wheel for alignment, with small concentricity deviation, compact structure, high transfer efficiency and low noise. The gear design of the reducer conforms to ISO or equivalent standards. The gear is made of low alloy steel, carburized, and the hardness of the gear surface is not less than hrc58. The reduction gearbox has lubrication, motor power is 0.75 × 2kW, protection grade is IP55, insulation grade is f, suitable for outdoor type, power supply is 380V, 3-phase, 50Hz.

Walking wheel: the walking wheel is installed at the bottom of the end beam, one at the front and one at the back, and directly runs at a speed of 2.5m per minute on the wall of the sedimentation tank. The walking wheel is made of iron core MC nylon, and the outer wheel is made of MC nylon, with high strength, generally over 5 years. According to the use data and user's report, MC nylon has not fallen off, cracked or seriously worn from the iron core.

Hot Tags: rotating sludge scraper, China, suppliers, manufacturers, factory, customized, price, OEM