Rotary Drum Screens For Industrial Wastewater

The rotary drum screens decontamination machine is a common equipment in sewage treatment, which can be used in sewage treatment plant, pump station and other places.

Send InquiryIntroduction

The rotary drum screens decontamination machine is a common equipment in sewage treatment, which can be used in sewage treatment plant, pump station and other places.

1. Domestic sewage and urban sewage

Domestic sewage is mainly the discharge water produced by the kitchen water, washing water and toilet water used in people's life. The sewage produced in the process of people's life is one of the main sources of water pollution.

2. Metal Smelting Wastewater

The water pollution of cooling water, casting and rolling steel is not very serious. The washing water is the waste water with more pollutants. For example, the waste water of dust removal and flue gas purification often contains a large number of suspended substances, which can be recycled only after being precipitated by the rotary drum screens cleaner, but the acid waste water and the water containing heavy metal ions are polluted.

3. Coking Gas Wastewater

Coking plant, city gas plant and so on produce serious pollution waste water in the process of coking and gas production, which contains a lot of impurities such as phenol, ammonia, sulfide, cyanide, tar and so on, which can produce various pollution effects.

4. Machining Wastewater

It mainly contains impurities such as lubricating oil and resin, waste liquid from machining metal products and washing water, and metal ions such as chromium, zinc and cyanide. Electroplating wastewater is one of the main industrial wastewater, which involves a wide range of areas and is highly polluting.

5. Wastewater from petroleum industry

It mainly includes three aspects: petroleum exploitation wastewater, refining wastewater and petrochemical wastewater. The oil-bearing waste water is discharged from the crude oil produced in the oil field in the process of dehydration treatment, which also contains a lot of dissolved salts, and its specific composition is related to the geological conditions of the oil-bearing formation.

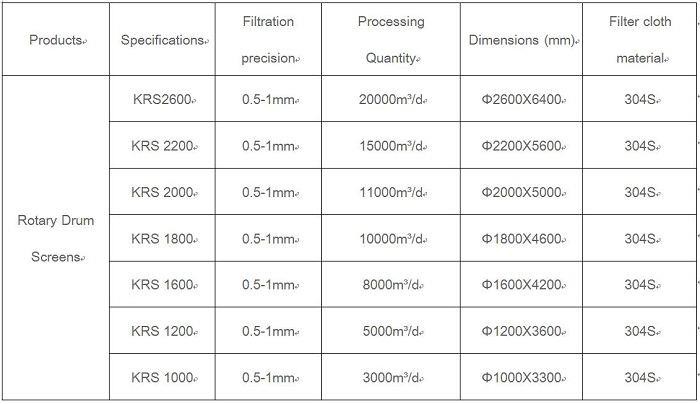

Technical parameters

Detail

Original: Jiangsu, China

Certification: ISO9001, ISO14001, etc.

Price: Negotiable

Material: SUS304/SUS316

Voltage: 380V 50Hz, the voltage can be as local demand

Payment term: TT, LC

Delivery date: Negotiable

Packing: export standard

Market: Middle East/ Africa/Asia/South America/Europe/North America

Warranty: 1 year

MOQ: 1 set

Equipment characteristics

The key materials of the drive equipment of the drum screens are all stainless steel plates. The power system is motor, and the speed reduction equipment is composed of cycloid reducer reducer and primary chain drive. The rotating shaft has sufficient compressive strength and bending rigidity to bear the load of bending and torsion together. Moreover, the reducer and chain drive equipment of the dynamic equipment are provided with maintenance covers, which is convenient for maintenance and inspection.

The total width of the spacing between grid bars shall meet the following requirements:

1 coarse grid: maintain 18mm-20mm.

2 fine grid: it should be 1.6mm-10 mm.

3 before centrifugal water pump, it should be based on the relevant parameters of centrifugal water pump.

4. 0.7m/s ~ 1.3m/s should be selected for the flow of wastewater through the grid. The installation angle of grating should be 30 ° - 65 °.

5. The inlet and outlet of drum grid, belt conveyor and dryer should be sealed, and deodorization device can be set according to the surrounding environment.

6. Keep natural ventilation between grids and set up inspection and alarm system for toxic and harmful substances.

Hot Tags: rotary drum screens for industrial wastewater, China, suppliers, manufacturers, factory, customized, price, OEM